The Rugged Thermal Cameras Market is witnessing steady growth as industries increasingly adopt advanced thermal imaging solutions capable of performing in extreme environments. These specialized devices are designed to withstand harsh weather, mechanical shocks, vibrations, and corrosive conditions while delivering accurate thermal detection and imaging. Their ability to operate reliably in demanding applications, such as defense, industrial inspection, firefighting, and maritime navigation, has positioned them as indispensable tools in multiple sectors. As technological advancements enhance imaging clarity, range, and portability, rugged thermal cameras are becoming critical assets for operational safety, predictive maintenance, and surveillance worldwide.

Market Drivers

One of the key drivers for market expansion is the rising demand for surveillance and monitoring systems that can function in adverse conditions, especially in the defense and security sectors. Governments and law enforcement agencies are increasingly investing in rugged thermal imaging for border security, search and rescue operations, and tactical missions. Similarly, the industrial sector benefits from these cameras in predictive maintenance, enabling early fault detection in machinery and electrical systems, thus reducing downtime and operational costs.

Another significant growth factor is the rising awareness of workplace safety. In industries such as oil and gas, mining, and manufacturing, rugged thermal cameras help detect overheating, gas leaks, or equipment malfunctions before they escalate into hazards. The adoption of Industry 4.0 technologies has further expanded integration opportunities for these cameras into automated inspection and monitoring systems.

Technological Advancements

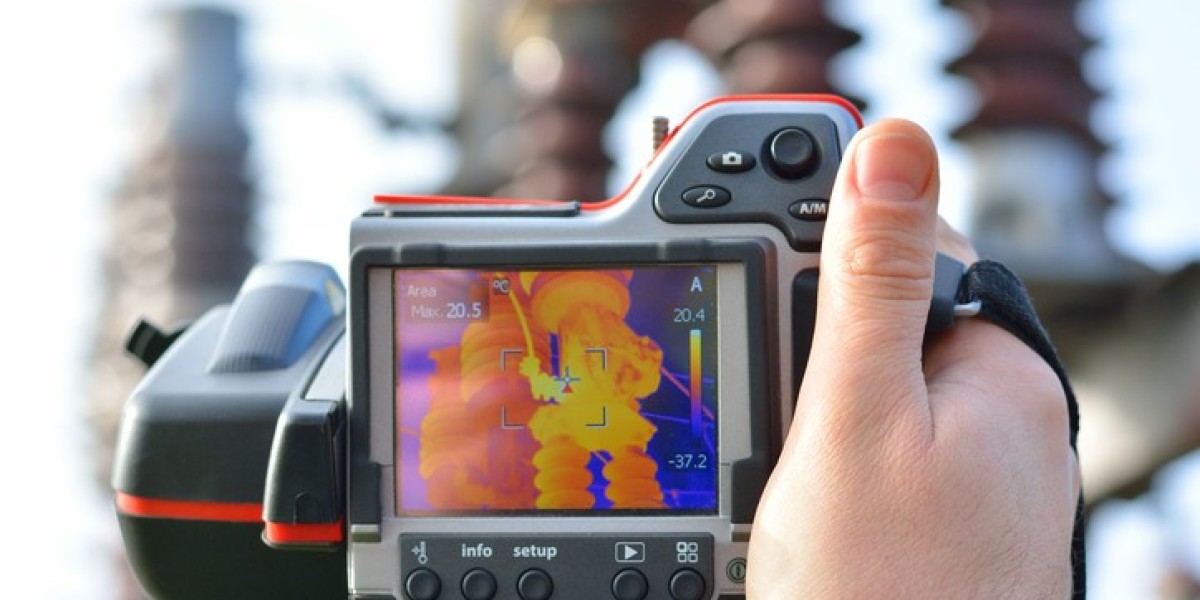

Recent developments in sensor technology, image processing, and connectivity are reshaping the rugged thermal cameras market. Innovations such as uncooled microbolometer sensors, higher resolution imaging, and advanced digital signal processing have significantly improved detection accuracy and image clarity. Additionally, integration with AI-based analytics allows automated anomaly detection and real-time alerts, enabling faster response times in critical applications.

Rugged thermal cameras are also increasingly incorporating wireless connectivity features such as Wi-Fi, Bluetooth, and LTE for remote monitoring. Compact and handheld designs, paired with extended battery life, make them more versatile and portable for field use. The growing adoption of augmented reality (AR) overlays and GPS integration further enhances usability, especially in outdoor and mission-critical environments.

Key Application Areas

Defense and Security: Rugged thermal cameras are extensively used for night vision, perimeter monitoring, and search and rescue operations in low-light or obscured conditions. Their ability to detect heat signatures beyond visible light makes them indispensable for tactical and covert missions.

Industrial Inspection: Industries leverage these cameras for monitoring equipment temperature, identifying insulation defects, and detecting electrical hotspots. In energy and utility sectors, they are crucial for maintaining grid stability and preventing power outages.

Firefighting: Thermal imaging aids firefighters in locating hotspots, navigating smoke-filled environments, and conducting post-fire assessments. Rugged designs ensure reliability even in extreme heat and challenging conditions.

Marine and Navigation: In maritime applications, rugged thermal cameras enhance navigation safety by detecting floating objects, other vessels, and navigational hazards in low visibility conditions.

Healthcare and Emergency Response: During the COVID-19 pandemic, thermal imaging devices were used for mass temperature screening. In ruggedized forms, they are suitable for field medical camps and remote health monitoring.

Regional Insights

North America currently holds a substantial market share due to high defense spending, technological leadership, and widespread adoption across industrial and emergency services. Europe follows closely, driven by safety regulations and the presence of advanced manufacturing facilities. The Asia-Pacific region is emerging as the fastest-growing market, fueled by infrastructure development, increasing defense budgets, and industrial expansion in countries like China, India, and Japan.

Competitive Landscape

The market features both established players and emerging innovators. Leading companies focus on product durability, high-resolution imaging, and AI integration to differentiate themselves. Strategic collaborations, mergers, and acquisitions are common as manufacturers seek to expand their geographic presence and product portfolios. Additionally, partnerships with software developers are enabling the creation of integrated solutions that combine thermal imaging hardware with powerful data analytics tools.

Future Outlook

The rugged thermal cameras market is expected to see strong growth through 2032, driven by:

Rising adoption in unmanned vehicles and drones for surveillance and inspection.

Miniaturization of components allowing lightweight, portable, and more affordable designs.

AI-powered thermal analytics enabling predictive maintenance and automated decision-making.

Expansion into new markets such as smart cities and autonomous navigation systems.

Environmental monitoring is another promising growth area. Rugged thermal cameras can detect heat loss in buildings, monitor wildlife, and track environmental hazards like forest fires, making them essential tools for sustainability initiatives.

Conclusion

The rugged thermal cameras market is evolving rapidly, fueled by technological innovation, increasing safety requirements, and expanding applications across industries. As manufacturers continue to improve durability, image quality, and connectivity, these devices will play an even greater role in critical operations, industrial safety, and environmental monitoring worldwide. With strong growth potential and diverse application opportunities, the industry is poised to remain a vital component of the global thermal imaging landscape.