Versatile Applications and Infrastructure Growth Drive Robust Market Outlook

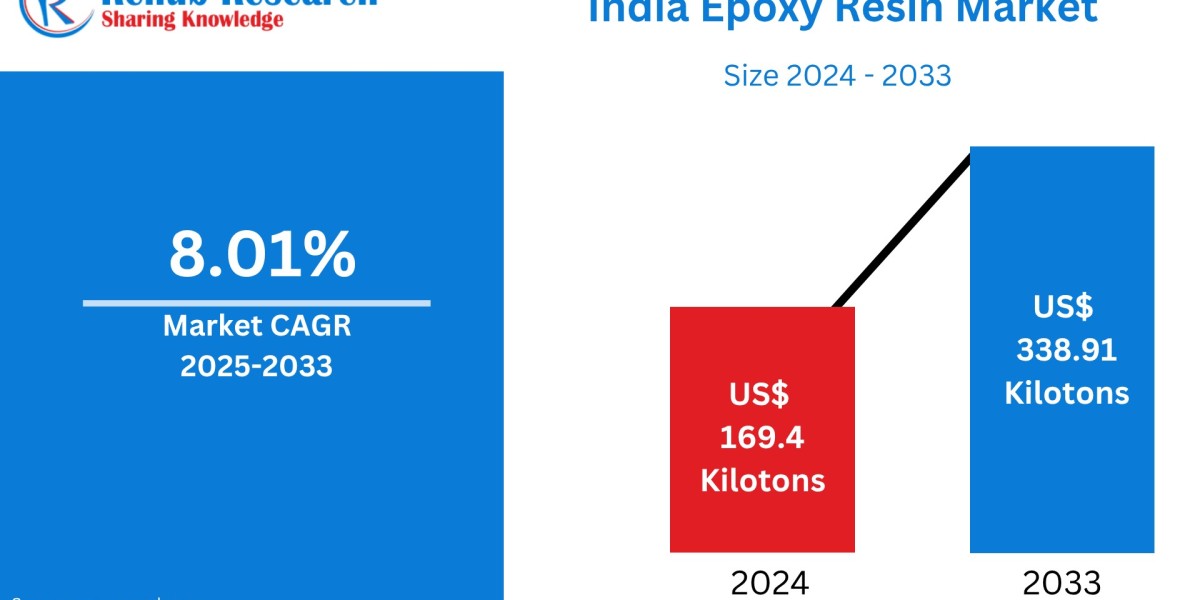

According to Renub Research, the India Epoxy Resins Market is undergoing rapid transformation, driven by the country’s expanding industrial base, infrastructure development, and increasing adoption of composite materials. Epoxy resins—known for their exceptional adhesion, mechanical strength, and chemical resistance—are witnessing surging demand from sectors such as automotive, construction, electrical & electronics, wind energy, paints & coatings, and adhesives.

Explore Full Report: India Epoxy Resins Market

Epoxy Resins: Backbone of Modern Industrial Materials

Epoxy resins are thermosetting polymers used across a variety of high-performance applications. Their unique properties—such as excellent moisture resistance, thermal stability, and strong bonding capabilities—make them essential to multiple industries in India.

In recent years, epoxy resins have become indispensable in the production of paints and coatings, printed circuit boards (PCBs), wind turbine blades, structural adhesives, automotive parts, and composite materials. As India accelerates its journey toward becoming a global manufacturing hub, epoxy resins are playing a critical role in enabling innovation and durability in end products.

Construction Sector Fuels Epoxy Demand

India’s fast-paced urbanization and infrastructure boom have made the construction industry a primary consumer of epoxy resins. Used in flooring, concrete bonding, sealants, and corrosion-resistant coatings, epoxy formulations are gaining popularity due to their performance in both residential and commercial construction.

Government initiatives like “Smart Cities Mission,” “PM Gati Shakti,” and “Housing for All” are stimulating demand for high-quality building materials. Epoxy flooring, in particular, is being adopted in commercial complexes, hospitals, and industrial facilities for its hygienic, durable, and aesthetic properties.

Automotive and Aerospace Industries Drive Innovation

India's automotive industry is evolving rapidly with growing adoption of lightweight and fuel-efficient materials. Epoxy resins are key ingredients in composites used for structural parts, under-the-hood components, and body panels that help reduce vehicle weight without compromising safety or performance.

With electric vehicle (EV) production on the rise, epoxy resins are also used in battery encapsulation, insulation, and adhesives, contributing to enhanced thermal and electrical performance.

The aerospace sector, though smaller in scale, is also adopting epoxy composites for their strength-to-weight advantages and heat resistance—making them ideal for both interior and structural components.

Wind Energy Sector Emerges as a Growth Catalyst

India’s increasing investment in renewable energy is fueling a new growth vertical for epoxy resins. In the wind energy sector, epoxy-based composites are widely used to manufacture rotor blades, nacelles, and other turbine components due to their high strength, weather resistance, and durability.

As India scales up its wind energy capacity to meet clean energy targets, the demand for high-performance epoxy systems is expected to soar. Manufacturers are also collaborating with global resin suppliers to create localized, cost-effective solutions that meet the unique demands of Indian climates and grid conditions.

Electronics and Electricals: An Expanding Market

India’s electronics manufacturing sector—bolstered by the "Make in India" initiative—is emerging as another major consumer of epoxy resins. These materials are essential in encapsulating electronic components, protecting circuit boards, and providing electrical insulation.

Epoxy encapsulants ensure long-term reliability of semiconductors, sensors, and other high-tech components by shielding them from heat, moisture, and physical stress. As India aims to reduce dependency on imports and boost domestic electronics production, the demand for specialized epoxy formulations is growing proportionately.

Paints, Coatings, and Adhesives: Steady Growth Continues

The Indian paints and coatings industry has consistently recorded strong growth, driven by real estate, automotive refinishing, infrastructure, and industrial maintenance. Epoxy-based coatings are preferred for their long-lasting finish, chemical resistance, and superior adhesion to metal and concrete surfaces.

Similarly, epoxy adhesives are used across the consumer and industrial sectors, offering high strength bonds for metal, glass, wood, and plastic materials. These applications are expanding rapidly in packaging, electronics, furniture, and consumer appliances.

Innovation and R&D Enabling Market Diversification

Epoxy resin producers in India are focusing on formulation customization, sustainability, and high-performance materials to cater to evolving industry demands. Low-VOC (volatile organic compound) formulations, water-based epoxy systems, and bio-based epoxy resins are gaining traction as environmental concerns become more pronounced.

Collaborations between chemical companies and research institutions are enabling the development of advanced grades of resins tailored for specific use-cases, such as fire-retardant formulations for aerospace or highly elastic grades for flexible electronics.

Regional Manufacturing Hubs and Import Substitution Strategies

India’s epoxy resins market is also benefiting from the expansion of local production facilities, especially in states like Gujarat, Maharashtra, and Tamil Nadu. These industrial hubs are home to leading resin manufacturers and component processors, contributing to supply chain efficiency and cost reduction.

With global supply chain disruptions highlighting the risks of over-reliance on imports, Indian manufacturers are accelerating domestic production of key raw materials such as epichlorohydrin (ECH) and bisphenol-A (BPA), used in epoxy resin synthesis.

Competitive Landscape: Strategic Expansion and Sustainability

The competitive landscape of India’s epoxy resins market includes both global players and domestic producers. Companies are investing in capacity expansion, product innovation, and sustainable practices to strengthen their market presence.

Key strategies include:

· Establishing greenfield plants and upgrading existing facilities

· Launching eco-friendly product lines

· Collaborating with downstream users for customized solutions

· Building robust distribution networks across Tier-2 and Tier-3 cities

As competition intensifies, innovation, quality, and customer support will remain the key differentiators.

Future Outlook: Strong Growth Trajectory Ahead

With a favorable policy environment, rising domestic demand, and expanding application base, the India Epoxy Resins Market is poised for consistent long-term growth. The increasing adoption of advanced materials across sectors such as EVs, aerospace, clean energy, and high-performance construction will be central to driving demand.

Discover the full market insights in Renub Research’s in-depth report, which provides comprehensive analysis on market segmentation, end-user trends, competitive landscape, and growth forecasts.

New Publish Report:

· Saudi Arabia Whiskey Market Size and Share Analysis - Growth Trends and Forecast Report 2025-2033

· Saudi Arabia Wine Market Size and Share Analysis - Growth Trends and Forecast Report 2025-2033

· Saudi Arabia Foodservice Market Trends, Growth & Forecast 2025–2033

About Renub Research

Renub Research is a Market Research and Consulting Company with more than 15 years of experience, especially in international Business-to-Business Research, Surveys, and Consulting. We provide a wide range of business research solutions that help companies make better business decisions.

We partner with clients across all sectors and regions to identify their highest-value opportunities, address their most critical challenges, and transform their businesses. Our wide clientele includes key players in Healthcare, Travel & Tourism, Food & Beverages, Power & Energy, Information Technology, Telecom & Internet, Chemicals, Logistics & Automotive, Consumer Goods & Retail, Building & Construction, and Agriculture.

Our core team comprises experienced professionals with graduate, postgraduate, and Ph.D. qualifications in Finance, Marketing, Human Resources, Bio-Technology, Medicine, Information Technology, Environmental Science, and more.

Media Contact:

Company Name: Renub Research

Contact Person: Rajat Gupta, Marketing Manager

Phone No: +91-120-421-9822 (IND) | +1-478-202-3244 (USA)

Email: rajat@renub.com

URL: https://www.renub.com/india-epoxy-resins-market-p.php