The use of packaging machines is a vital part of efficient and automated industries. As a result of investing in these machines, industries such as food and beverage, pharmaceuticals, and consumer goods have successfully automated and increased operational efficiency. To make better investment decisions regarding automation, enterprises must first understand what packaging machines are and how they operate and diversify.

The Advancement of Industry Packaging Machines

The use of packaging machines at automation and packaging stations pose to save time, character, and operational costs in the packaging process as the machines carry out: filling, sealing, wrapping, and palletizing. As well as protective wrapping, machines also weigh and store, and remove products in packets, cartons, and crates, and maintain constant cycle times separated competitive sealed products. With industry machines, packaging time and size of the workforce can be reduced, and transportation and protective storage cost decreased.

Packaging machines have significantly reduced the fatigue and physical demand for people supervising the systems, and operational standards and productivity increased. Bottlenecks in the process line have been reduced and the entire process is now able to work steadily with minimal human interference. Machines have replaced people in the process of packaging, and it can be performed continuously without the need for human attention.

The industrial packaging industry incorporates different types of packaging machines based on the functions they serve, the types of containers they handle, and the volumes of containers they produce. Packaging automation solutions range from small countertop units for packaging startups to large automation systems for packaging entire lines with a throughput of several thousand units every hour, thereby catering to the packaging needs of almost every business.

Main Parts and Their Functioning

No matter the type of packaging system, every system integrates a number of basic parts that interact. The system of machine Feeding integrates packed products or materials into the machine in a controlled manner. During the operation, Conveyors move packed products to different processing stations and then to the exit. Conveyors use sensors to detect, track, and monitor the position and quality of packed products.

The control system of the machine synchronizes the mechanical parts to ensure the different processing stages operate in harmony. Pneumatic cylinders, servo motors, and hydraulic systems are diverse Actuators that provide the force to perform different tasks in the packaging process. Sealers of the packaging system use heat, ultrasonic energy, or pressure to form and maintain packed closures. To form the packed products, dispensing systems in the packaging machine measure and provide the required contents into the containers.

For modernized packaging equipment, safety features like emergency stop buttons, safety guards, light curtains, and interlock systems that stop the equipment when access doors are opened, are all inclusive. These safety features not only protect the operator, but they also respond to the occupational health and safety requirements.

Types of Packaging Machines by Function

According to the packaging industry, the basic order of operations when packaging is completed determines the machinery used. The most important category of machinery used to package product is the filling machine. These instruments are used to package product of all forms, liquids, powders, granules, and pieces - they all fit into containers, and they need to be filled with the exact amount of product the machine is designed to dispense. The systems that used to be implemented were basic systems with only gravity and the modern systems used today are servo-driven systems that can achieve an incredibly precise fill of a few grams.

Form-fill-seal machines use roll stock film to create containers, fill them with product, and then seal them. These machines are particularly designed to package food by making and sealing pouches, sachets, and bags through continuous operations. Form-fill-seal systems are flexible and can be tailored to specific needs. The manufacturer of packaging machine often specializes to specific form-fill-seal systems to address individual industry needs.

Shrink wrapping systems, stretch film applicators, and overwrapping machines are all part of the wrapping equipment family. These devices encase items in a protective film. Labeling machines affix pressure-sensitive, glue-applied, or sleeve labels to containers, which are vital for brand identification and product information. Cartoning machines automate the erection, loading, and closing of cartons, while case packing equipment arranges items into shipping cases.

Specialized Bulk Packaging Solutions

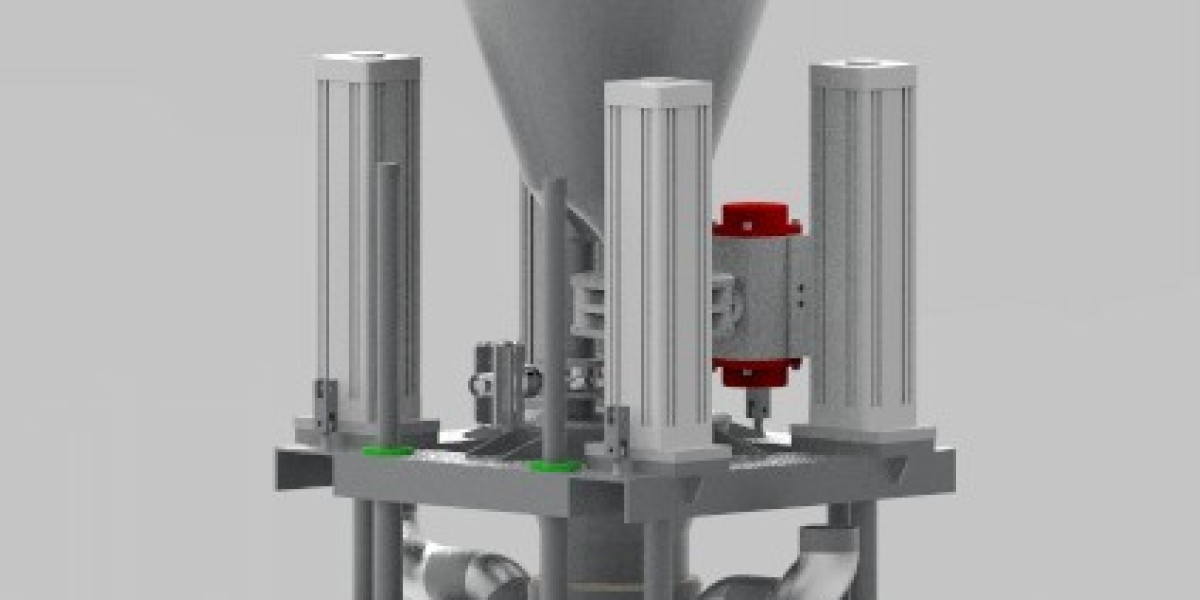

Specialized bulk packaging equipment is important for material handling and distribution for industries that deal with large-volume materials. The best Jumbo bag filling machine or bulk bag filler and FIBC (Flexible Intermediate Bulk Container) filler is designed to fill large bags that weigh from 500 to over 2,000 kilograms. These systems are made of heavy materials and have load cells, accurate weighing, dust collection systems, and bag inflation mechanisms that ensure the bags are properly seated.

Bulk bag filling systems usually have several filling spouts, automated bag attachment frames, and densification systems which use vibration or mechanical compaction to increase the bag's capacity. The control systems on these machines are designed to store several product recipes and automatically adjust filling parameters based on material characteristics like bulk density, flowability, and particle size.

Sectors like chemical manufacturing, mineral extraction, agriculture, plastic production, and pharmaceuticals use high-capacity filling machinery and equipment. With the use of jumbo bag fillers, a significant portion of routine and manual tasks are automated, which decreases the risk associated with lifting and improves the safety of the workplace. This also helps maintain consistent filling weights, thus reducing product giveaway and improving a company's bottom line.

Valve Bag Filling Technology

Another class of specialized packaging technology helps industries that need accurate filling of open-mouth and valve bags. The advanced paper valve bag filling machine packs multi-wall paper bags through a small valve opening, which seals automatically after filling, thanks to the internal product pressure. This packaging technique is useful for powdered and granular products that need to be protected from moisture and contamination.

There are two methods of filling valve bags: air packing and impeller packing. In air packing, pressurized air is used to fluidize the product and then convey it into the bag. In impeller packing, a mechanical system is used to push the material into the filling spout. Modern valve bag fillers are equipped with automatic bag placement, accurate weight measurement and dust-tight filling systems that maintain a dust-free working environment.

These machines cater to the construction materials, chemicals, foodstuffs, and agriculture industries. Such industries distribute products including cement, mortar, animal feed, flour, and powdered chemicals in 10 to 50 kg valve bags. With the automation of modern valve bag equipment, industries can fill bags at a speed of 600 to 1,200 bags per hour, depending on the product and bag size.

Integration of Smart Technology and Industry 4.0

The principles of Industry 4.0 initiated a technological shift in the packaging industry. For instance, new packaging machines incorporating the Internet of Things (IoT) technology allow for the real-time monitoring of a machine's operation and its predictive maintenance and remote troubleshooting.

Sensors along the machine gather data on numerous parameters such as cycle times, reject rates, temperature and pressure. Such data is sent to manufacturing execution systems (MES) and enterprise resource planning (ERP) systems. This offers managerial staff a complete picture of the production system’s efficiency, equipment effectiveness (OEE), and quality parameters. Predictive maintenance is enabled through machine learning and historical data on machine performance, which helps eliminate unplanned production downtimes.

AI-enhanced vision systems identify problematic packages and quality control issues at high speed. Such systems identify improperly sealed containers, missing and misplaced labels, containers over and under filled, and damaged containers. Automated quality control systems make and sustain product quality leaving little room manual inspections and possible customer complaints or product recalls.

Material Handling and Product Protection

The essential purpose of all packaging operations goes beyond just enclosing product. It must protect the product throughout the entire distribution chain, which means protecting it and mitigating possible damages. After all, packaging machines are built to handle products in a manner that does minimize damages, which is of utmost importance for fragile items, food products that are crushable, and pharmaceutical products that must remain uncontaminated.

Different materials require different handling approaches. Free-flowing granular products can be packaged at high speeds using gravity-fed systems, while cohesive powders may require auger fillers or densification equipment. Positive displacement pumps are used for sticky or viscous liquids, whereas thinner liquids can be dealt with overflow fillers or timed flow filling systems.

Choosing suitable containers and compatible materials and securing them for transportation are key challenges to overcome to prevent damage. Glass containers are fragile, and fillers must be careful, while flexible fillers also need to be supported, or they may tip and spill. The packaging materials, be they plastic films, paper, aluminum, or composites, must also be matched to the product to prevent contamination and avoid transmission of moisture and chemical reactions.

Hygiene and Sanitary Design Considerations

Whenever there are concerns for hygiene, such as in food, beverage, and pharmaceuticals, the packaging machines must then be made of stainless steel. Sanitary design requires that contact surfaces are smooth without crevices to serve as harbors for bacteria, and that machines be designed for easy, tool-less disassembly to facilitate thorough cleaning. More advanced CIP and SIP systems are designed for disinfection and cleaning without the need to disassemble the machine. Automated record systems provide the documentation needed for traceability, to meet regulatory requirements, and for quality audits.

Aseptic packaging technology reaches the highest levels of sanitation by sterilizing the product and packaging material and filling within a sterile environment. This makes it possible to create shelf-stable products that do not require refrigeration and increases the potential for extended product shelf life and distribution. Aseptic filling lines require large capital investments, but the competitive advantages they provide in several markets are also large.

Customization and Application-Specific Solutions

Standardized packaging machines effectively serve many applications, but many more industries require specialized, customized solutions. In these cases, equipment manufacturers collaborate closely with their customers to create specialized machinery that addresses particular challenges posed by abrasive materials, explosive dusts, temperature-sensitive products, unusual container shapes, and other more proprietary obstacles.

Examples of custom packaging solutions might include specialized dosing systems that ensure extremely accurate fills, shelf-life extension by modified atmospheres, or other integration features that create seamless flow with upstream and downstream equipment. The engineering process must consider product properties, required production volumes, available floor space, and existing utilities.

Incorporating modularity into machine design enables configurational and spatial alterations in the future. Machines can also have additional stations designed in such a way that they can be activated when production volumes increase. Quick changeovers can be implemented between different product variants and package sizes using interchangeable tooling. Such flexibility translates into long-term economic value and justifies the value of the machinery, as the economic value of packaging machines is often significant.

Justifying an investment in any kind of automated packaging equipment calls for an economic assessment. Automated packaging lines, especially those designed for high-speed packaging, require high capital investments, and specialized equipment often incurs additional expenses. Generally, the justification comes from labor savings, automated lines enhance production capabilities, and they provide high uniformity and quality of the final product, which in turn limits product giveaways, and provides high disposal savings.

Automating packaging lines is usually the most practical investment in labor savings, especially in countries with high labor costs and where finding workers is challenging. Automation decreases the number of workers required for a shift and allows the system to run with minimal supervision for long periods. Automated systems also enhance uniformity of the packaged products, which decreases the number of customer complaints and the product's rework or disposal.

Material savings stem from accurate filling to avoid overfilling, sealing time and energy minimization to optimize seal strength, and decreased packaging damage that eliminates the need for repackaging. These small savings add up over millions of packages and translate to a considerable cost savings over the course of a year.

Maintenance and Support to Achieve Operational Excellence

The value of a comprehensive maintenance program that includes preventive maintenance, spare parts inventory control, and addressing unforeseen equipment breakdowns promptly to ensure the packaging machinery runs is paramount. Maintenance schedules are provided by equipment manufacturers, and these schedules outline the lubrication points, replacement timing and intervals of wear parts, and adjustments to perform on the equipment.

They also define the operating range of the equipment and in some cases, include automation that performs some of the tasks for the operator. Trained operators are the first line of maintenance and support. They will notice trouble developing and act to prevent an equipment failure. They will safely perform a change over to a different product or size of package and maintain a close within the limits of the prescribed operating range.

Support from equipment suppliers varies considerably. Factors include hours of support (business hours, 24/7), time of response, remote diagnostics, and on-site service. For primary production lines where downtime is extremely costly, developing a service relationship and keeping spare parts will protect against long downtimes.

Sustainability and Environmental Responsibility

All stakeholders in the supply chain and operations want to mitigate the impact of operations on the environment and want to improve the sustainability of the supply chain. Sustainability and Environmental Responsibility for every component in the supply chain, including packaging, requires attention to detail in multiple areas such as material usage, recyclable and compostable material use, energy consumption, waste generation, and transport emissions. Sustainability and Environmental Responsibility for packaging machinery encompasses all the above considerations.

Sustainability efforts can include minimizing the weight of the packaging materials used for packaging each individual product. Adaptive controls on packaging equipment improve the efficiency of material use through management of lighter, thinner, and flexible materials for each product. Thin films mean a lot in packaging as the weighted average and the total weight of the films used in packaging over many products make a significant difference.

Sustainability efforts can include minimizing the weight of the packaging materials used for packaging each individual product. Adaptive controls on packaging equipment improve the efficiency of material use through management of lighter, thinner, and flexible materials for each product. Thin films mean a lot in packaging as the weighted average and the total weight of the films used in packaging over many products make a significant difference.

Future Trends and Technological Evolution

Consumer preferences, regulatory requirements, and technology use determine how fast and how the shift occurs within the packaging industry. The packaging machinery industry has increased levels of automation, and the use of robotics is growing, particularly for the task of quality inspection, of case packing, and of palletizing, all of which require human judgment and dexterity.

The flexible packaging market continues to expand due to efficiencies the material provides and due to convenience for consumers. This growing market is driving demand for advanced form-fill-seal equipment. Machines designed to perform smart packaging functions, incorporating RFID, QR codes, and time-temperature indicators, need packaging machinery for the application of and for the verification of these functions during the packaging process.

The need for quick-changeover equipment for smaller batch sizes, and increased product variety lead to greater demand. Touchscreen servo-driven machines and recipe management systems help systems achieve format changes in minutes rather than hours, allowing economically smaller lot sizes just in time for manufacturing.

The deeper integration of packaging machines within automated overall manufacturing systems is the next phase. Bidirectional communication streamlines packaging operations to automatically adjust to predetermined packing levels and to varying real-time production schedules, material availability, and customer order priorities, thus helping to achieve smart factory objectives.

The advancements seen in packaging machinery are indicative of changes within the manufacturing sector as a whole, including greater automation, integration, flexibility, and sustainability within production systems. The rise in sophistication of automated packaging machinery allows businesses of all scales to automate their packaging processes in order to compete on the global market, all while satisfying the rising quality, efficiency, and eco-friendly demands of the market.