In the world of industrial and mechanical applications, the importance of reliable sealing solutions cannot be overstated. Sealing rings play a critical role in preventing leaks, maintaining pressure, and ensuring the efficient operation of machinery. Among the various materials used for sealing rings, silicone has emerged as a standout choice, particularly for high-temperature environments. RuiXiang Silicone, a leading manufacturer in the industry, has developed high-temperature silicone sealing rings that are setting new standards for performance and durability. This article delves into the features, benefits, and applications of these innovative sealing solutions.

What Are High-Temperature Silicone Sealing Rings?

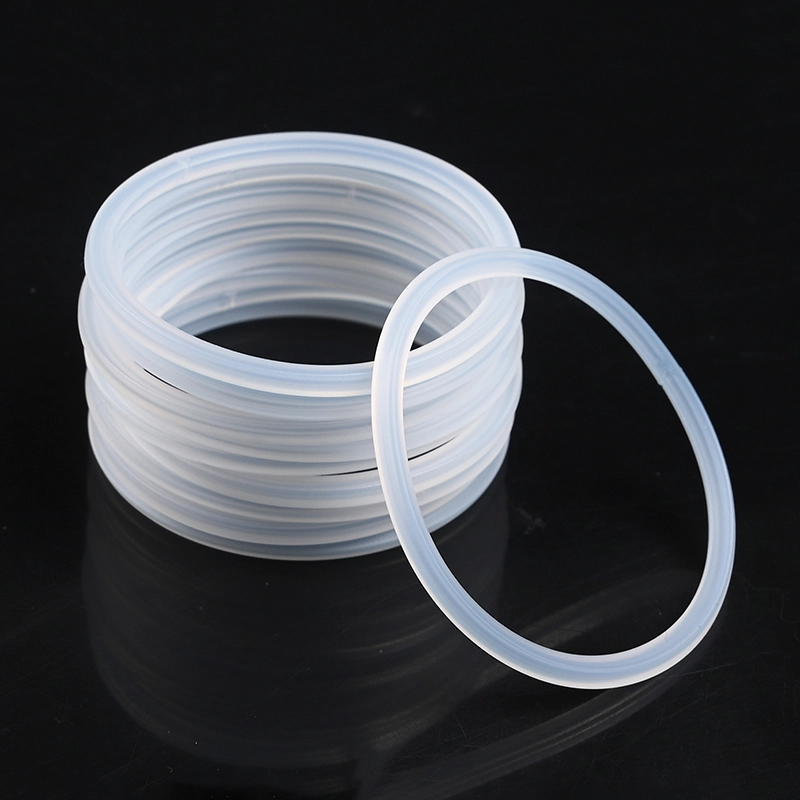

High-temperature silicone sealing rings are specialized components designed to withstand extreme heat while maintaining their structural integrity and sealing capabilities. Unlike traditional rubber or plastic seals, which can degrade or fail under high temperatures, silicone-based seals are engineered to perform reliably in environments where temperatures can soar. RuiXiang Silicone’s sealing rings are crafted from premium-grade silicone, which is known for its exceptional thermal stability, flexibility, and resistance to aging. These properties make them ideal for use in industries where exposure to heat is a constant challenge.

Key Features of RuiXiang Silicone’s Sealing Rings

RuiXiang Silicone’s high-temperature sealing rings boast several features that set them apart from conventional sealing solutions. First and foremost is their ability to withstand temperatures ranging from -60°C to 300°C (-76°F to 572°F), making them suitable for both extreme cold and heat. Additionally, these rings exhibit excellent resistance to ozone, UV radiation, and weathering, ensuring long-term performance even in harsh outdoor conditions.

Another notable feature is their chemical resistance. Silicone seal ring Silicone’s sealing rings are impervious to a wide range of chemicals, including acids, alkalis, and solvents. This makes them versatile for use in industries such as chemical processing, where exposure to corrosive substances is common. Furthermore, the rings are highly flexible and elastic, allowing them to maintain a tight seal even under dynamic conditions where movement or vibration is present.

Benefits of Using High-Temperature Silicone Sealing Rings

The advantages of using high-temperature silicone sealing rings from RuiXiang Silicone are numerous. One of the primary benefits is their longevity. Thanks to their resistance to heat, chemicals, and environmental factors, these seals have a significantly longer lifespan compared to traditional materials. This translates to reduced maintenance costs and fewer replacements, saving both time and money for businesses.

Another key benefit is their reliability. In high-temperature applications, the failure of a seal can lead to catastrophic consequences, including equipment damage, safety hazards, and costly downtime. RuiXiang Silicone’s sealing rings provide peace of mind by ensuring a consistent and reliable seal, even under the most demanding conditions.

Additionally, these sealing rings are environmentally friendly. Silicone is a non-toxic material that does not release harmful substances, making it a sustainable choice for industries looking to reduce their environmental impact. The durability of silicone also means less waste generated over time, further contributing to eco-friendly practices.

Applications of High-Temperature Silicone Sealing Rings

The versatility of RuiXiang Silicone’s high-temperature sealing rings makes them suitable for a wide range of applications across various industries. In the automotive sector, they are used in engines, exhaust systems, and turbochargers, where they must endure high temperatures and exposure to oils and fuels. In the aerospace industry, these seals are critical for ensuring the integrity of aircraft components subjected to extreme thermal conditions.

The food and beverage industry also benefits from these sealing rings, particularly in equipment used for cooking, sterilization, and processing. Silicone’s non-toxic nature and resistance to high temperatures make it an ideal material for ensuring food safety and compliance with industry regulations.

In the manufacturing and energy sectors, high-temperature silicone sealing rings are used in machinery, pipelines, and power generation equipment. Their ability to withstand heat and chemical exposure ensures the efficient and safe operation of these systems. Even in medical and pharmaceutical applications, where precision and reliability are paramount, these seals play a vital role in maintaining sterile environments and preventing contamination.

Why Choose RuiXiang Silicone?

RuiXiang Silicone has established itself as a trusted name in the silicone products industry, and for good reason. The company combines cutting-edge technology with rigorous quality control processes to deliver products that meet the highest standards. Their high-temperature silicone sealing rings are no exception, offering unmatched performance and durability.

Moreover, RuiXiang Silicone is committed to customer satisfaction. They work closely with clients to understand their specific needs and provide customized solutions tailored to their requirements. Whether it’s a unique size, shape, or material formulation, RuiXiang Silicone has the expertise to deliver.

Conclusion

High-temperature silicone sealing rings from RuiXiang Silicone represent a significant advancement in sealing technology. With their exceptional thermal stability, chemical resistance, and durability, these seals are an ideal choice for industries that demand reliable performance under extreme conditions. By choosing RuiXiang Silicone, businesses can ensure the longevity and efficiency of their equipment while reducing maintenance costs and environmental impact. Whether in automotive, aerospace, food processing, or energy applications, these sealing rings are a testament to the power of innovation and quality in solving real-world challenges.