Label printing plays a vital role in daily operations across various industries. From product packaging to barcode labeling, clear and durable prints are essential for accuracy. Thermal Transfer Ribbons in UAE meet this demand with high-quality results suited for different environments. These ribbons are commonly used in sectors like logistics, retail, healthcare, and manufacturing. They provide smudge-resistant, long-lasting prints that remain readable over time. Thermal transfer printing works by applying heat to transfer ink from the ribbon onto the label. The durability of the print depends on the ribbon type and label surface. UAE businesses face unique challenges like heat, humidity, and fast-paced logistics. That’s why selecting the right ribbon type—wax, wax-resin, or resin—is critical. Understanding each type helps ensure reliable, cost-effective labeling for your operations.

1. What Are Thermal Transfer Ribbons?

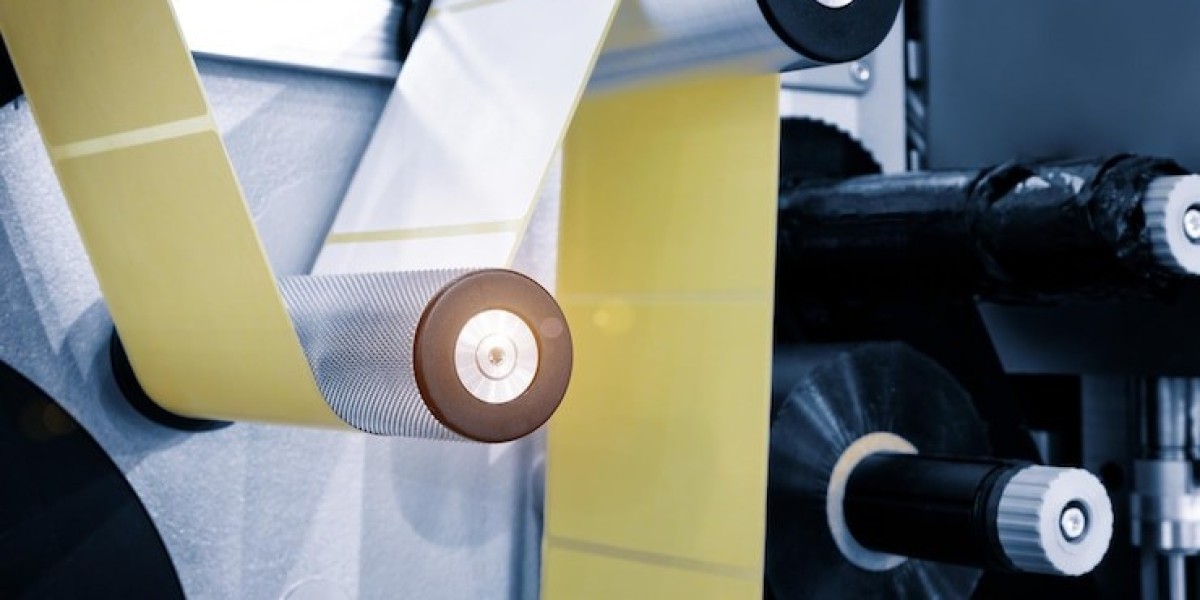

Thermal transfer ribbons are rolls of coated film used in thermal transfer printers. These ribbons contain ink that melts when heated by the printhead, transferring the ink onto the label material. The result is a durable, smudge-resistant image that can last for years, depending on the ribbon and label combination.

There are three main types of ribbons:

Wax Ribbons – Best for general-purpose use. Ideal for paper labels.

Wax-Resin Ribbons – Offer more durability and better resistance to smudging.

Resin Ribbons – Provide the highest durability. Suitable for synthetic labels.

Each type meets different labeling needs, from short-term inventory tracking to long-lasting outdoor labeling.

2. Common Applications in the UAE

Thermal transfer ribbons serve a wide range of sectors in the UAE:

Retail – Price tags, shelf labels, and inventory management.

Logistics and Shipping – Shipping labels that withstand handling and heat.

Healthcare – Patient wristbands, specimen labels, and medical packaging.

Manufacturing – Labels for chemicals, electronics, and industrial goods.

Food Industry – Product labeling with resistance to moisture and refrigeration.

Oil & Gas – Durable tags for outdoor and harsh environments.

Different applications require different levels of durability and resistance. Choosing the right ribbon ensures readability and prevents print failures.

3. Wax, Wax-Resin, and Resin Ribbons: Key Differences

Here's a short breakdown of each ribbon type:

1. Wax Ribbons

Use: Ideal for standard paper labels.

Durability: Basic resistance to smudging.

Cost: Most affordable option.

Common Use: Retail and warehouse inventory.

2. Wax-Resin Ribbons

Use: Works on both coated paper and synthetic materials.

Durability: Better resistance to scratches and chemicals.

Cost: Mid-range.

Common Use: Shipping, healthcare, and food packaging.

3. Resin Ribbons

Use: Best for synthetic labels like polyester and polypropylene.

Durability: Highest resistance to chemicals, water, and abrasion.

Cost: Premium.

Common Use: Laboratory, industrial, and outdoor labeling.

Matching the ribbon to the label material and application is essential for performance and cost-efficiency.

4. Factors to Consider When Choosing a Ribbon in the UAE

When selecting thermal transfer ribbons, consider the following:

Label Material

Paper labels work well with wax ribbons.

Synthetic labels need wax-resin or resin ribbons.

Print Durability

For short-term use, choose wax ribbons.

For exposure to chemicals or water, go with resin ribbons.

Environmental Conditions

High humidity, heat, or sunlight demand more durable ribbons.

UAE’s climate makes resin ribbons ideal for outdoor applications.

Printing Speed

Wax ribbons can handle faster printing.

Resin ribbons work slower but offer higher quality.

Printer Compatibility

Ensure the ribbon matches the printer model and printhead type.

Flat-head and near-edge printers require different ribbon types.

Cost and Volume

For high-volume, low-cost printing, wax ribbons are efficient.

For critical labeling, invest in resin ribbons.

5. Industries in the UAE That Benefit from Thermal Transfer Ribbons

Several UAE industries rely heavily on these ribbons:

Pharmaceuticals: Precise labeling helps meet strict health regulations.

E-commerce: Fast and readable barcode labels support delivery services.

Chemical Industry: Durable labels resist solvents and abrasion.

Retail Chains: Manage pricing and stock effectively.

Logistics Companies: Ensure smooth scanning and tracking of packages.

Food Processing: Labels survive cold storage and handling.

In all these sectors, thermal transfer ribbons play a vital role in ensuring operational continuity.

6. How to Store and Handle Thermal Transfer Ribbons

Proper handling increases the shelf life and performance:

Store ribbons in a cool, dry place.

Avoid direct sunlight and high humidity.

Do not bend or crease the ribbon rolls.

Use clean hands or gloves during installation.

Keep spare rolls sealed until use.

Good storage prevents damage and ink smudging during printing.

7. Common Issues and How to Prevent Them

Here are a few issues and simple tips to avoid them:

Poor Print Quality

Use compatible ribbon and label material.

Check printer settings.

Ribbon Wrinkling

Ensure proper tension and alignment in the printer.

Printhead Damage

Use high-quality ribbons.

Clean the printhead regularly.

Faded Printing

Replace old ribbons.

Adjust heat settings.

Following the correct setup and maintenance guidelines ensures clear and long-lasting prints.

8. Conclusion

Thermal transfer ribbons in the UAE are critical for businesses that need reliable and long-lasting label printing. From basic wax ribbons to high-durability resin types, the right ribbon improves productivity and accuracy. By understanding the types, uses, and selection criteria, businesses can choose the best ribbon for their operations. Whether you're labeling shipping boxes or chemical containers, proper ribbon selection ensures durability, clarity, and compliance