In the modern industrial era, businesses constantly seek ways to improve productivity, reduce waste, and deliver higher value to customers. Concepts like Lean Management, Six Sigma, the 5S Method, and Kaizen have emerged as powerful methodologies in achieving operational excellence. At the forefront of implementing these tools in India is SugoyaIndia, a company dedicated to transforming businesses through process optimization and sustainable growth strategies.

This blog explores these four pivotal methodologies and how they can revolutionize the workplace, enhance overall equipment efficiency, and align with Industry 4.0 innovations.

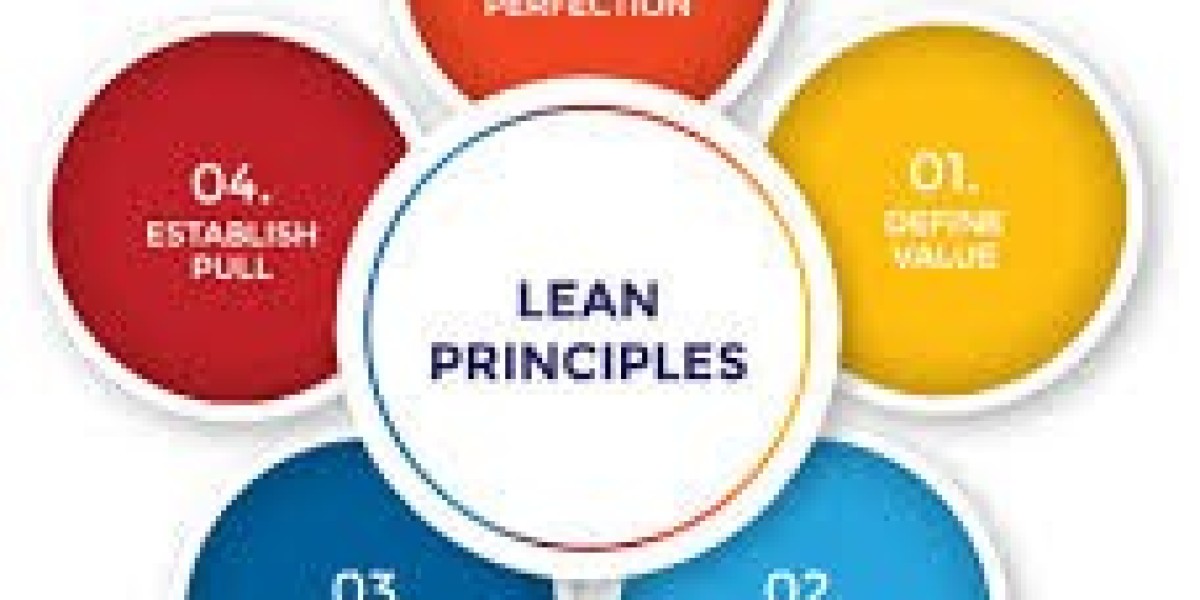

Understanding Lean Management Principles

Lean Management is a business philosophy that focuses on delivering more value to the customer by eliminating waste. Originating from the Toyota Production System, lean management prioritizes continuous improvement, streamlined processes, and efficient workflows.

Companies implementing lean management benefit from improved quality, reduced lead times, and lower costs. At SugoyaIndia, lean practices are seamlessly integrated with digital transformation to ensure companies are future-ready.

Core Lean Management Principles:

Define value from the customer’s perspective.

Map the value stream.

Create continuous workflow.

Establish pull systems.

Pursue perfection through continuous improvement.

When applied correctly, these principles help increase overall equipment efficiency, reduce downtime, and improve resource utilization.

The Role of Six Sigma in Process Optimization

Six Sigma is a data-driven methodology that seeks to reduce process variation and enhance quality. It uses the DMAIC framework (Define, Measure, Analyze, Improve, Control) to solve problems and optimize processes.

At SugoyaIndia, Six Sigma is tailored to the unique challenges of each business. The lean and six sigma combination delivers even greater results by integrating lean’s speed and waste reduction with Six Sigma’s quality control.

Benefits of Six Sigma:

Minimizes defects to less than 3.4 per million opportunities.

Improves customer satisfaction.

Reduces operational costs.

Enhances compliance and standardization.

Organizations that adopt lean six sigma practices often see significant improvements in delivery performance, customer satisfaction, and financial outcomes.

5S Method: Foundation of a Productive Workplace

The 5S method is a workplace organization tool that lays the foundation for efficiency and safety. It includes five steps—Sort, Set in order, Shine, Standardize, and Sustain.

SugoyaIndia provides expert guidance in implementing the 5S system in manufacturing, warehousing, and office environments. The visible impact of this method can be seen in cleaner workspaces, reduced downtime, and better employee morale.

5S in the Workplace Involves:

Sort (Seiri): Remove unnecessary items.

Set in Order (Seiton): Organize tools and equipment logically.

Shine (Seiso): Keep the workspace clean.

Standardize (Seiketsu): Develop uniform procedures.

Sustain (Shitsuke): Instill discipline to maintain improvements.

The 5S in the workplace not only boosts productivity but also lays the groundwork for overall equipment efficiency and operational excellence.

Kaizen: Continuous Improvement for Sustainable Success

Kaizen is a Japanese term that means "change for the better." It is a continuous improvement process that involves all employees, from the CEO to the shop floor workers.

At SugoyaIndia, the Kaizen process is embedded into company culture to promote innovation and problem-solving. Unlike large-scale changes, Kaizen in process improvement emphasizes small, incremental improvements that compound over time.

Key Elements of Kaizen:

Team collaboration and participation.

Daily improvement cycles.

Root cause analysis and corrective action.

Employee empowerment and training.

When applied across departments, Kaizen leads to improved quality, faster delivery, lower costs, and higher employee satisfaction.

How These Methods Work Together

Integrating lean management, six sigma, the 5s method, and kaizen creates a synergy that transforms business operations. While each technique can drive results independently, their combined application—known as lean six sigma—delivers greater efficiency, enhanced quality, and consistent growth.

By adopting these strategies, organizations can improve overall equipment efficiency, eliminate bottlenecks, and build a culture focused on continuous improvement.

Why Choose SugoyaIndia?

SugoyaIndia stands out as a trusted partner in implementing operational excellence frameworks. Whether it's guiding businesses through lean transformations, leading Six Sigma projects, or deploying 5S systems, SugoyaIndia ensures a customized approach that aligns with strategic goals.

With experience across industries and a passion for innovation, SugoyaIndia helps organizations embrace modern practices like lean management principles and kaizen process to achieve sustainable success.

Frequently Asked Questions (FAQs)

Q1. What is the main goal of lean management?

A: The main goal of lean management is to maximize customer value while minimizing waste. It focuses on creating efficient processes and eliminating non-value-added activities.

Q2. How does Six Sigma differ from Lean?

A: Lean focuses on process speed and waste elimination, while Six Sigma is concerned with reducing variation and improving quality. Together, they form the lean six sigma methodology.

Q3. What are the 5S steps in the workplace?

A: The 5S in the workplace includes Sort, Set in Order, Shine, Standardize, and Sustain. It enhances workplace organization, safety, and productivity.

Q4. How is Kaizen implemented in a company?

A: Kaizen is implemented by encouraging employees to suggest small improvements regularly. These are then tested, refined, and standardized across processes.

Q5. Can these methodologies be used together?

A: Yes. Combining lean management, six sigma, 5s method, and kaizen leads to comprehensive improvements in quality, efficiency, and performance.

Q6. What industries benefit most from these practices?

A: Manufacturing, healthcare, logistics, IT services, and retail industries greatly benefit from these practices due to their process-driven nature.

Conclusion

Incorporating proven methodologies like lean management, six sigma, the 5S method, and kaizen can dramatically enhance your business operations. These approaches promote waste reduction, quality improvement, employee engagement, and customer satisfaction.

If you're looking to future-proof your organization with these powerful tools, SugoyaIndia provides tailored solutions and expert guidance. Start your journey toward operational excellence today with the best practices in lean, Six Sigma, 5S, and Kaizen.