The global Tool Holder Market is experiencing significant growth, driven by increasing demand for high-precision machining, advancements in CNC technology, and the rising adoption of automation across various industries. As manufacturers seek enhanced efficiency and accuracy, tool holders have become essential components in machining processes, ensuring stability, precision, and longevity of cutting tools.

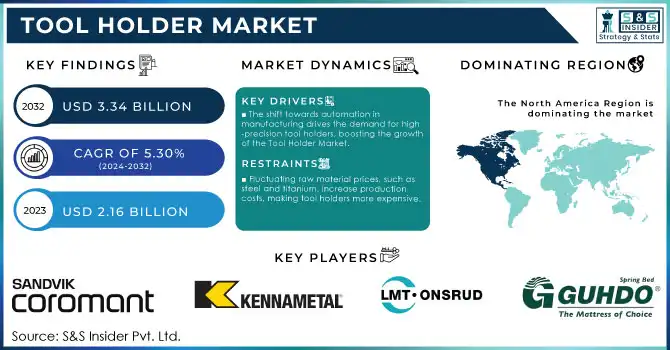

The Tool Holder Market Size was esteemed at USD 2.16 billion in 2023 and is supposed to arrive at USD 3.34 billion by 2032 and develop at a CAGR of 5.30% over the forecast period 2024-2032.

Key Market Drivers

- Surging Demand for High-Precision Manufacturing

The growing focus on precision engineering, particularly in industries such as aerospace, automotive, medical devices, and electronics, is fueling the demand for advanced tool holders. These components ensure optimal tool positioning, minimizing vibrations and improving cutting performance. - Expansion of CNC Machining and Automation

With the rapid adoption of Computer Numerical Control (CNC) machines across industries, the need for high-performance tool holders has risen significantly. Innovations in tool holder designs, such as hydraulic tool holders, shrink-fit tool holders, and collet chucks, are enhancing machining efficiency and reducing downtime. - Growth in Aerospace and Automotive Industries

The automotive and aerospace sectors continue to drive demand for cutting-edge tool holders. As these industries prioritize lightweight materials, such as titanium and composites, precision machining becomes essential, boosting the need for advanced tool-holding solutions. - Adoption of Smart Tool Holding Technologies

Industry 4.0 and smart manufacturing trends are transforming the tool holder market. The integration of sensor-based tool holders enables real-time monitoring of cutting forces, tool wear, and vibration levels, improving productivity and predictive maintenance.

Market Segmentation

- By Type: Hydraulic Tool Holders, Shrink Fit Tool Holders, Collet Chuck Tool Holders, Milling Tool Holders, and Others

- By Material: Carbide, Steel, and Others

- By Industry: Automotive, Aerospace & Defense, Electronics, Medical, General Manufacturing, and Others

Future Outlook

The Tool Holder Market is expected to witness robust growth, particularly in regions such as North America, Europe, and Asia-Pacific, with China, Japan, and Germany emerging as key manufacturing hubs. Continuous investments in automation, AI-driven machining, and sustainable manufacturing practices will further shape the market's evolution.

Key Players

- GUHDO

- Bilz Tool

- LMT Onsrud

- TAC Rockford

- Gem Precision Tool

- Kennametal

- Sandvik Coromant

- KTA Spindle Toolings

- CERATIZIT

- SECO

- Haimer

- BIG Kaiser

- Wright Tool

- Dormer Pramet

- Mitsubishi Materials

- Röhm

- Bison-Bial

- Tool-Flo Manufacturing

- Schunk

- Guhring

Conclusion

As industries embrace advanced machining solutions, the demand for innovative and high-performance tool holders will continue to rise. Companies investing in R&D, smart technologies, and precision engineering will be well-positioned to capitalize on the expanding opportunities in this dynamic market.

For more details @ https://www.snsinsider.com/reports/tool-holder-market-2642

Contact Us:

Akash Anand – Head of Business Development & Strategy

info@snsinsider.com

Phone: +1-415-230-0044 (US)