The long fiber thermoplastics (LFT) market is experiencing significant growth, driven by increasing demand from automotive, aerospace, consumer electronics, and industrial applications. These advanced materials offer a high strength-to-weight ratio, durability, and recyclability, making them ideal for lightweight and high-performance applications. This article explores the key trends, market growth factors, and future outlook for the global long fiber thermoplastics market.

Market Size & Regional Insights

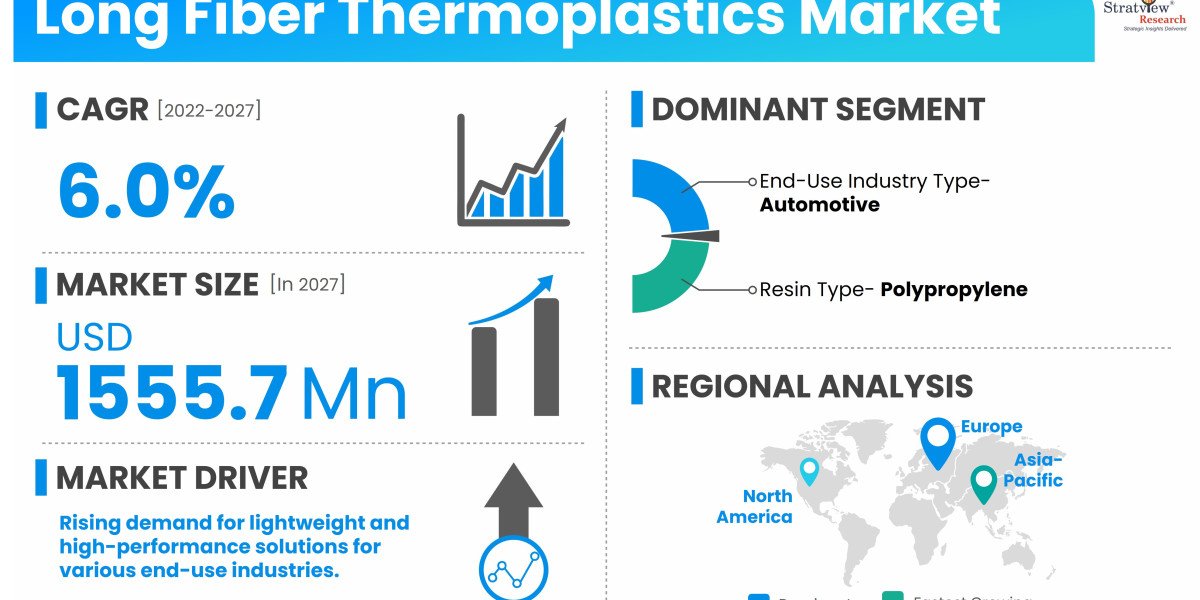

According to Stratview Research, the long fiber thermoplastics market was estimated at USD 1,057.7 million in 2021 and is likely to grow at a CAGR of 6% during 2022-2027 to reach USD 1,555.7 million in 2027.

Europe held more than 35% of the share in 2021 and expected to remain dominant during the forecast period.

Europe is the home of leading automotive OEMs, tier players, and LFT manufacturers. Germany and Belgium are the manufacturing capitals of LFTs in the region. Asia Pacific is expected to witness the highest CAGR of 7.6% during 2022-2027 driven by China, Japan, and India. China was one of the markets that experienced an excellent recovery amid the pandemic.

Future Challenges and Opportunities

While the long fiber thermoplastics market is on a strong growth trajectory, challenges such as high production costs, complex processing techniques, and competition from alternative composites need to be addressed. However, advancements in material science, sustainable production, and innovative applications present significant growth opportunities for the industry.

Key Market Trends

1. Growing Demand for Lightweight Materials: Industries such as automotive and aerospace are shifting towards lightweight yet durable materials to improve fuel efficiency, reduce emissions, and enhance performance. LFTs, being stronger and more durable than short-fiber thermoplastics, are becoming the material of choice for structural components.

2. Expansion in Automotive and Transportation Sectors: The automotive industry is one of the largest consumers of LFTs, using them in interior panels, front-end modules, under-the-hood components, and bumpers. With the increasing adoption of electric vehicles (EVs), the demand for lightweight materials like LFTs is expected to rise, further driving market growth.

3. Advancements in Manufacturing Technologies: New production techniques, such as injection molding, compression molding, and 3D printing, are improving the efficiency and performance of LFTs. These advancements are making LFTs more accessible and cost-effective, accelerating their adoption across multiple industries.

4. Sustainability and Recyclability: With an increasing focus on sustainable and eco-friendly materials, LFTs are gaining traction due to their recyclability and reduced environmental impact. Manufacturers are investing in bio-based and recycled fiber-reinforced thermoplastics, aligning with global sustainability goals.

Conclusion

The long fiber thermoplastics market is set for substantial expansion, fueled by lightweight material demand, automotive and aerospace innovations, and sustainability trends. With continuous technological advancements and increasing investments in R&D, LFTs will continue to shape the future of high-performance materials