The global Friction Stir Welding (FSW) Equipment Market is experiencing rapid growth, driven by increasing demand for high-strength, defect-free welds across industries such as aerospace, automotive, shipbuilding, and railways. As manufacturers seek advanced welding techniques that enhance efficiency, reduce material waste, and improve mechanical properties, FSW is emerging as a preferred solution due to its ability to join materials without melting them.

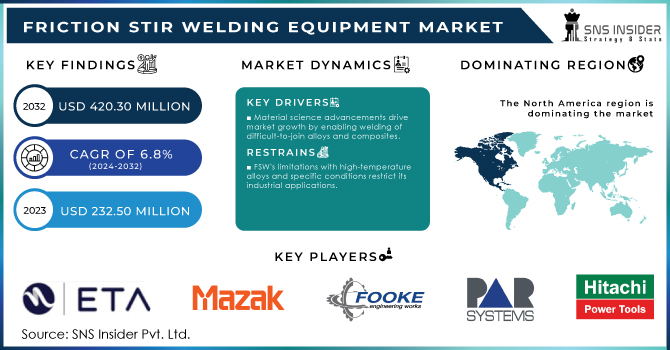

The Friction Stir Welding Equipment Market Size was valued at USD 232.50 Million in 2023 and is now anticipated to grow USD 420.30 Million by 2032, displaying a compound annual growth rate (CAGR) of 6.8% during the forecast Period 2024-2032.

Key Market Drivers

- Growing Adoption in Aerospace and Automotive Sectors

The aerospace industry is leveraging FSW technology for producing lightweight and high-strength structures, particularly in aluminum-based components. Similarly, the automotive industry is incorporating FSW for manufacturing lightweight vehicles that improve fuel efficiency and reduce emissions. - Advancements in FSW Technology

Innovations in friction stir welding machines, including robotic and automated FSW systems, are enhancing precision, consistency, and production speed. These advancements are making FSW more viable for mass production and complex applications. - Rising Demand for High-Strength Welds

Traditional welding methods often lead to defects such as porosity and cracks, whereas FSW eliminates such issues by operating below the melting point of materials. This results in stronger, more reliable joints, making it a preferred choice in industries requiring high structural integrity. - Sustainability and Cost-Effectiveness

FSW is an eco-friendly welding technique as it eliminates the need for filler materials, reduces energy consumption, and minimizes emissions. The cost-effectiveness of FSW, particularly in large-scale industrial applications, is further driving its adoption.

Market Segmentation

- By Equipment Type: Fixed FSW Machines, Portable FSW Machines, Robotic FSW Systems

- By End-Use Industry: Aerospace, Automotive, Shipbuilding, Railway, Electronics, and Others

Key Players

- ETA Technology

- YAMAZAKI MAZAK CORPORATION

- FOOKE GmbH

- PAR Systems

- Hitachi Power Solutions Co., Ltd.

- NITTO SEIKI CO., LTD.

- Grenzebach Group

- Bond Technologies

- PTG

- Groupe TRA-C Industrie

Conclusion

The Friction Stir Welding Equipment Market is set to expand significantly in the coming years, fueled by technological advancements, increasing industrial applications, and a growing focus on lightweight, high-performance materials. As leading players continue to invest in automation, material compatibility, and large-scale adoption, FSW is expected to revolutionize the welding industry.

For more details @ https://www.snsinsider.com/reports/friction-stir-welding-equipment-4436

Contact Us:

Akash Anand – Head of Business Development & Strategy

info@snsinsider.com

Phone: +1-415-230-0044 (US)