The 3D printing materials market is evolving rapidly, driven by a combination of technological advancements, industry demands, and changing consumer preferences. As additive manufacturing becomes more mainstream, understanding the various factors that impact this market is crucial for stakeholders looking to capitalize on opportunities and navigate challenges. This article delves into the key influencing factors affecting the 3D printing materials market, examining the roles of innovation, regulatory frameworks, consumer demands, and environmental considerations.

Technological Advancements

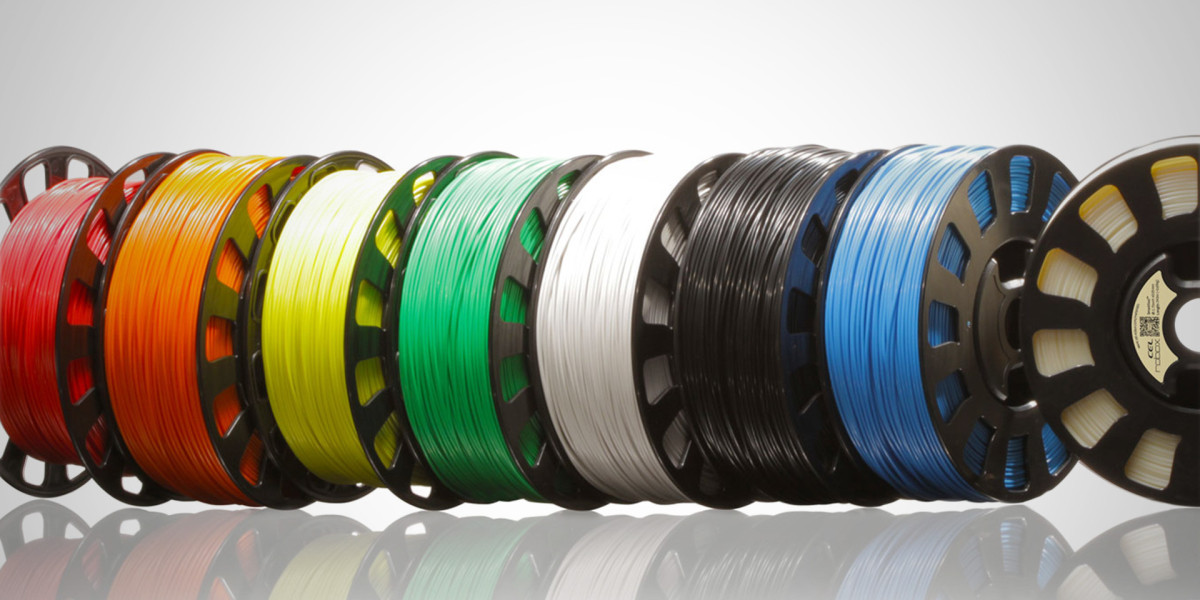

One of the most significant factors influencing the 3D printing materials market is the rapid pace of technological advancements. As 3D printing technology evolves, the range and quality of available materials have expanded dramatically. Initially dominated by basic polymers, the market is now witnessing the introduction of high-performance materials, including metals, ceramics, and composites.

Advancements in printing techniques, such as binder jetting, selective laser sintering, and fused deposition modeling, have also enhanced the capabilities of additive manufacturing. These technologies allow for more intricate designs, better surface finishes, and improved material properties, leading to broader applications across industries. As companies continue to innovate and refine their technologies, the demand for advanced materials that meet specific performance criteria is likely to grow, shaping the future of the 3D printing materials market.

Industry-Specific Demands

The demands of various industries significantly impact the 3D printing materials market. Sectors such as aerospace, automotive, healthcare, and consumer goods each present unique requirements that drive the development of specialized materials. For instance, the aerospace industry requires lightweight, high-strength materials to improve fuel efficiency and reduce production costs.

In healthcare, the focus is on biocompatible materials that can be used for implants and medical devices. The automotive sector seeks materials that enable rapid prototyping and customization, enhancing design flexibility and reducing lead times. As these industries continue to evolve, the need for tailored materials that address specific challenges will shape the direction of the 3D printing materials market, driving innovation and growth.

Regulatory Environment

The regulatory landscape plays a crucial role in shaping the 3D printing materials market. As the technology matures and finds applications in critical sectors such as aerospace and healthcare, regulatory bodies are increasingly focusing on ensuring the safety and efficacy of 3D printed products. Compliance with stringent safety standards and quality regulations can significantly influence the development and adoption of new materials.

Manufacturers must navigate complex regulatory requirements to bring their products to market, often involving extensive testing and validation processes. The evolving regulatory environment may pose challenges for companies seeking to introduce innovative materials. However, it also creates opportunities for those willing to invest in research and development to meet these standards, ultimately contributing to market growth.

Consumer Preferences

Changing consumer preferences are another vital factor impacting the 3D printing materials market. As consumers become more aware of the benefits of 3D printing, there is an increasing demand for personalized products that reflect individual tastes and lifestyles. This shift towards customization has implications for material development, as manufacturers must create versatile materials that can accommodate a wide range of applications.

The consumer goods sector, in particular, is witnessing a surge in demand for unique, tailored products. From personalized fashion items to bespoke home decor, the ability to create customized solutions efficiently through 3D printing is reshaping the market landscape. Companies that can respond to these evolving consumer demands will be well-positioned to capture market share and drive innovation.

Environmental Considerations

Environmental considerations are increasingly influencing the 3D printing materials market. As sustainability becomes a priority for both consumers and industries, the demand for eco-friendly materials is on the rise. Traditional manufacturing processes often result in significant waste and pollution, prompting a search for more sustainable alternatives.

3D printing offers inherent advantages in this regard, as it is an additive process that minimizes material waste. Additionally, the development of bio-based and recyclable materials is gaining traction, providing opportunities for manufacturers to align their products with sustainability goals. Companies that prioritize environmentally friendly materials will not only meet consumer expectations but also position themselves as responsible industry players.

Market Competition and Collaboration

The competitive landscape of the 3D printing materials market is another factor shaping its dynamics. As more companies enter the market, competition intensifies, driving innovation and price pressures. In this environment, collaboration among stakeholders, including material developers, technology providers, and end-users, is essential for fostering innovation and improving product offerings.

Partnerships and collaborative research initiatives can lead to the development of new materials and technologies that address specific industry challenges. By working together, stakeholders can share knowledge and resources, accelerating the pace of innovation and enhancing the overall capabilities of 3D printing.

Looking Forward

The 3D printing materials market is influenced by a multitude of factors, including technological advancements, industry-specific demands, regulatory environments, consumer preferences, and environmental considerations. These influences collectively shape the trajectory of the market, presenting both challenges and opportunities for stakeholders.

As industries continue to embrace additive manufacturing, staying attuned to these impacting factors will be critical for success. By understanding and responding to the dynamics of the market, companies can position themselves to thrive in this rapidly evolving landscape, ultimately contributing to the growth and innovation of the 3D printing materials market in the years to come.