Manganese sulfate is a critical industrial compound widely used in various sectors, including agriculture, animal feed, and battery manufacturing. It is primarily used as a micronutrient in fertilizers and animal feed, providing essential manganese that promotes growth and health. Recently, manganese sulfate has gained significant attention for its role in the production of lithium-ion batteries, particularly for electric vehicles (EVs), where it is used in cathodes to improve battery performance.

The demand for Manganese Sulfate Price Forecast is on the rise, driven by global agricultural needs and the rapid growth of the EV industry. Understanding price trends and forecasting future prices for manganese sulfate is essential for stakeholders in the agriculture, automotive, and manufacturing sectors. This forecast provides insights into the factors influencing manganese sulfate prices and expectations for future price movements.

Historical Price Trends of Manganese Sulfate

1. Overview of Price Trends in the Past Decade

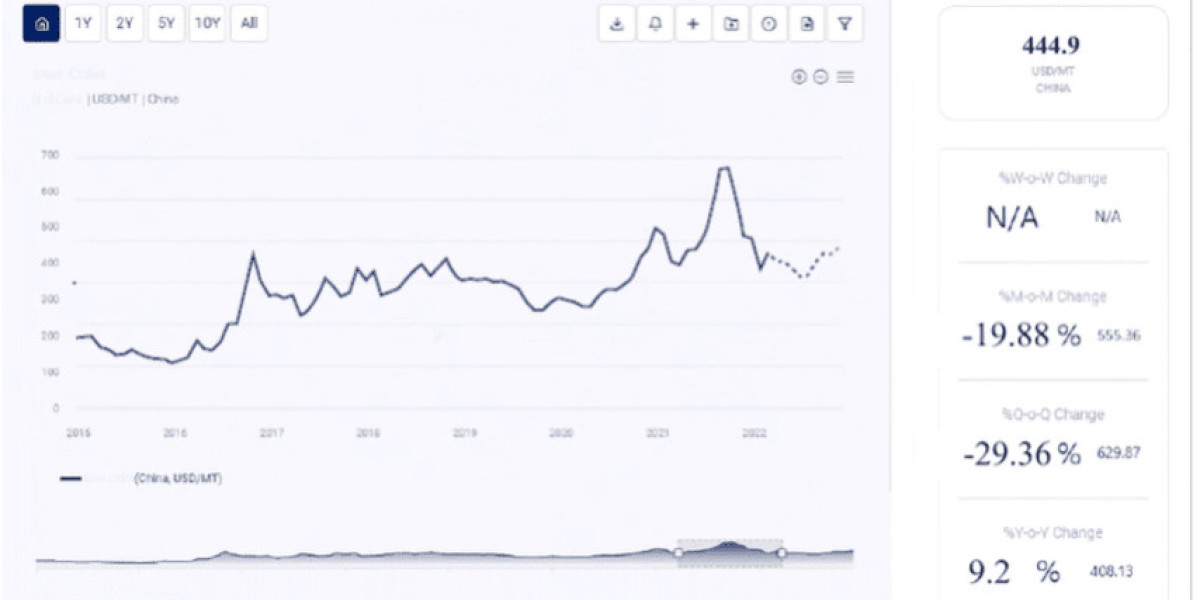

Over the past decade, the price of manganese sulfate has shown considerable volatility, primarily influenced by demand fluctuations from agriculture and manufacturing, as well as changes in raw material costs.

Agricultural Demand: Traditionally, demand for manganese sulfate has been tied to agricultural applications. Manganese sulfate is commonly used in fertilizers as a key micronutrient, and its price is influenced by seasonal agricultural cycles and crop yields. Prices generally rise during planting seasons and fall after harvest.

Battery Market Influence: In recent years, the battery manufacturing sector, especially the production of lithium-ion batteries, has become a major driver of manganese sulfate demand. The shift towards electric vehicles and renewable energy storage has increased demand for high-purity manganese sulfate, leading to significant price increases in regions with high battery production.

2. Impact of the COVID-19 Pandemic on Prices

The COVID-19 pandemic had a mixed impact on manganese sulfate prices. During the initial lockdowns, demand from various industrial sectors declined, causing a temporary dip in prices. However, as economies began to recover and the EV market surged, demand for battery-grade manganese sulfate increased, pushing prices higher.

Additionally, pandemic-induced supply chain disruptions led to increased transportation costs, logistical delays, and raw material shortages, all of which contributed to upward pressure on manganese sulfate prices. These trends underscored the importance of manganese sulfate for the EV market and revealed vulnerabilities in its supply chain.

Enquire For Regular Prices: https://www.procurementresource.com/resource-center/manganese-sulfate-price-trends/pricerequest

Key Factors Influencing Manganese Sulfate Prices

1. Demand from the EV and Battery Sectors

The EV industry is one of the fastest-growing markets for manganese sulfate, particularly battery-grade manganese sulfate, which is essential for producing lithium-ion batteries. The rise of electric mobility has created a substantial demand for battery materials, with manganese sulfate playing a crucial role in enhancing battery efficiency and energy density.

As countries implement stricter emissions standards and shift toward renewable energy, the demand for EVs is expected to grow, thereby increasing the demand for manganese sulfate. This demand surge is likely to impact prices significantly in the coming years, particularly if supply struggles to keep pace with the rapid expansion of battery manufacturing.

2. Agricultural Demand and Seasonal Variations

Agriculture remains a key market for manganese sulfate, which is widely used as a micronutrient in fertilizers. Manganese sulfate helps improve crop yields and resistance to diseases, making it essential for sustainable farming practices. Seasonal variations in planting and harvesting cycles lead to fluctuations in manganese sulfate demand, impacting prices during peak seasons.

In addition, climate change is affecting agricultural productivity, leading farmers to use more fertilizers, including manganese sulfate, to maintain crop yields. This increased usage, combined with seasonal demand, is likely to contribute to price volatility in the manganese sulfate market.

3. Supply Chain Constraints and Production Costs

Manganese sulfate production is heavily dependent on the availability of raw manganese ore, which is mined in regions like China, South Africa, and Australia. Factors that impact manganese ore mining and processing, such as geopolitical tensions, environmental regulations, and mining restrictions, can influence manganese sulfate supply and prices.

Mining and Refining Costs: The cost of extracting manganese ore and refining it into manganese sulfate affects the final product price. Rising energy prices and environmental regulations are increasing the costs of mining and refining operations, which could lead to higher manganese sulfate prices.

Supply Chain Vulnerabilities: The supply chain for manganese sulfate is global, with much of the refining and processing occurring in Asia. Disruptions in international logistics, such as container shortages or shipping delays, can impact the availability and price of manganese sulfate on the global market.

4. Regulatory Policies and Environmental Standards

Environmental regulations and policies aimed at reducing emissions and promoting clean energy sources play a significant role in the manganese sulfate market. The push for electric vehicles and renewable energy storage systems has increased demand for battery materials, including manganese sulfate. At the same time, regulations in mining and refining regions, aimed at reducing environmental impact, can increase production costs and influence supply.

Electric Vehicle Mandates: Government policies supporting electric vehicle adoption contribute to the increased demand for battery-grade manganese sulfate. Many countries, including the U.S., European nations, and China, have set targets for phasing out internal combustion engines, which is expected to drive up manganese sulfate demand and prices.

Environmental Restrictions on Mining: Regulations governing mining practices in manganese-rich regions can limit the availability of manganese ore, affecting manganese sulfate production. Strict environmental guidelines can increase production costs and reduce the supply, which may lead to price increases.

Contact Us:

Company Name: Procurement Resource

Contact Person: Leo Frank

Email: sales@procurementresource.com

Toll-Free Numbers:

- USA & Canada: +1 307 363 1045

- UK: +44 7537171117

- Asia-Pacific (APAC): +91 1203185500

Address: 30 North Gould Street, Sheridan, WY 82801, USA