The global Investment Casting Market is experiencing substantial growth, driven by increasing demand for high-precision and complex-shaped components across various industries. Investment casting, also known as lost-wax casting, is widely adopted for manufacturing intricate metal parts with superior surface finish and dimensional accuracy. This casting technique is gaining traction in sectors such as aerospace, automotive, defense, energy, and healthcare, where high-performance and lightweight materials are essential for efficiency and durability.

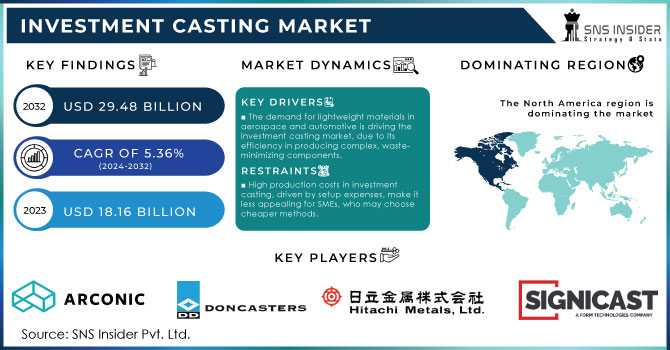

The Investment Casting Market Size was valued at USD 18.16 billion in 2023 and is expected to reach USD 29.48 billion by 2032, expanding at a CAGR of 5.36% over the forecast period 2024-2032. The market's growth is fueled by advancements in casting technologies, the rising adoption of lightweight alloys, and the increasing focus on precision engineering. Additionally, the growing shift toward sustainable and energy-efficient manufacturing processes is encouraging the adoption of investment casting, as it minimizes material wastage while delivering high-quality components.

Key Market Drivers

- Rising Demand for High-Precision Components

Investment casting is the preferred choice for industries requiring intricate and high-strength components with minimal post-processing. Sectors such as aerospace and automotive are increasingly adopting this casting method for manufacturing turbine blades, engine components, and structural parts to enhance fuel efficiency and performance. - Expansion in the Aerospace and Defense Sectors

The aerospace and defense industries are among the leading consumers of investment cast components. With the rising demand for next-generation aircraft and advanced defense equipment, manufacturers are relying on investment casting to produce lightweight, durable, and high-performance parts that meet stringent industry standards. - Growth of the Automotive Industry

Automakers are leveraging investment casting to develop lightweight and high-strength components for improved fuel efficiency and reduced emissions. The increasing adoption of electric vehicles (EVs) is further propelling demand for precision-cast aluminum and titanium parts, contributing to market expansion. - Advancements in Materials and Additive Manufacturing

Continuous advancements in material science, including the development of superalloys, titanium, and stainless steel, are enhancing the capabilities of investment casting. Additionally, the integration of additive manufacturing (3D printing) with investment casting is streamlining the production process, reducing lead times, and enabling the manufacturing of complex geometries with greater precision. - Growing Adoption in Medical and Industrial Applications

The medical sector is witnessing increased usage of investment casting for producing surgical instruments, orthopedic implants, and prosthetics with high accuracy and biocompatibility. Moreover, industrial machinery and power generation sectors are utilizing investment-cast components for critical applications, further driving market demand.

Key Players

- Arconic, Inc.

- Doncasters Group Ltd.

- Hitachi Metals, Ltd.

- MetalTek International

- Signicast

- Precision Castparts Corp (Berkshire Hathaway)

- Zollern GmbH and Co. KG

- Impro Precision Industries Limited

- Rogers Corp.

- Alcoa Corporation

- Apex Foundry

- Eisenmann Corporation

- Castrol

- Lisi Aerospace

- Kern-Liebers Group

- Töddler Foundry

- Luminant Capital

- Ferrostaal GmbH

- Harrison Castings Ltd.

- Shaanxi Tisky International

Conclusion

The Investment Casting Market is set for steady growth as industries continue to seek high-precision and cost-effective manufacturing solutions. With ongoing technological advancements, increasing adoption in aerospace, automotive, and healthcare, and the integration of advanced materials, the market is poised for long-term expansion. Companies focusing on innovation, automation, and sustainable manufacturing practices will gain a competitive edge in this evolving landscape. As demand for high-performance components rises, investment casting will remain a key manufacturing process shaping the future of precision engineering.

For more details @ https://www.snsinsider.com/reports/investment-casting-market-4649

Contact Us:

Jagney Dave - Vice President of Client Engagement

Phone: +1-315 636 4242 (US) | +44- 20 3290 5010 (UK)