The Advantages of Automatic Spray Paint Systems

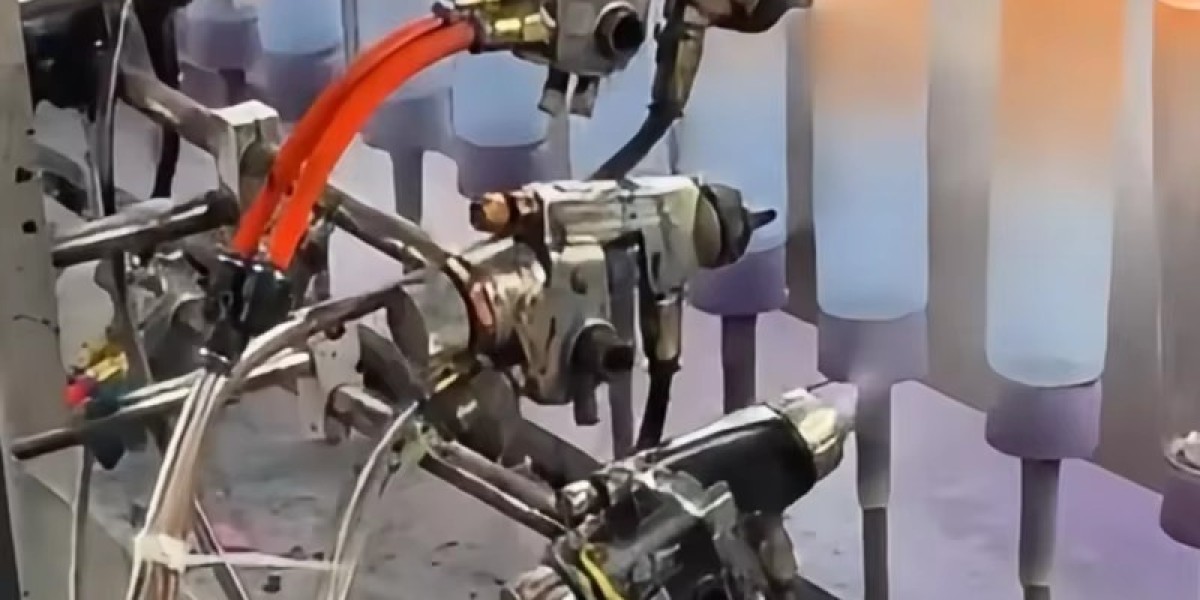

Automatic spray paint systems are designed to streamline the painting process, reducing the time and labor required for manual applications. By automating this critical phase of production, manufacturers can achieve higher output rates without compromising quality. These systems utilize advanced technology to ensure even coating, minimizing the risk of defects and ensuring that every product meets stringent quality standards. Furthermore, the precision of automatic systems allows for the use of a wider range of paint materials, enabling manufacturers to explore new finishes and colors that appeal to their customers.

Cost Efficiency and Waste Reduction

Implementing automatic spray paint systems can lead to significant cost savings over time. Traditional manual painting methods often result in excessive waste due to overspray and inconsistent application. In contrast, automatic systems are engineered to optimize paint usage, reducing material costs and minimizing environmental impact. This not only aligns with modern sustainability goals but also enhances the overall profitability of manufacturing operations. By investing in automatic spray paint systems, companies can future-proof their manufacturing processes against rising material costs and regulatory pressures related to waste management.

Enhanced Flexibility and Customization

Today's consumers demand personalized products, and automatic spray paint systems are equipped to meet this challenge. With programmable settings and adjustable parameters, these systems allow manufacturers to quickly switch between different paint types and colors, accommodating short production runs and custom orders with ease. This flexibility is crucial in a market where trends shift rapidly and customer preferences evolve. By adopting automatic spray paint systems, manufacturers can position themselves as leaders in customization, attracting a broader customer base and increasing market share.

Integrating Technology and Innovation

As manufacturing continues to embrace Industry 4.0 principles, the integration of technology in production processes becomes increasingly important. Automatic spray paint systems are often equipped with smart features, such as real-time monitoring and data analytics, allowing manufacturers to track performance and identify areas for improvement. This data-driven approach enables companies to make informed decisions that enhance operational efficiency and product quality. By investing in these innovative systems, manufacturers not only enhance their current capabilities but also lay the groundwork for future advancements in production technology.

In conclusion, automatic spray paint systems are an essential investment for manufacturing businesses looking to enhance efficiency, reduce costs, and meet the demands of an ever-changing market. By embracing these advanced technologies, companies can future-proof their operations, ensuring they remain competitive and responsive to customer needs. The benefits of implementing automatic spray paint systems extend beyond immediate gains, positioning manufacturers for long-term success in a dynamic industry.