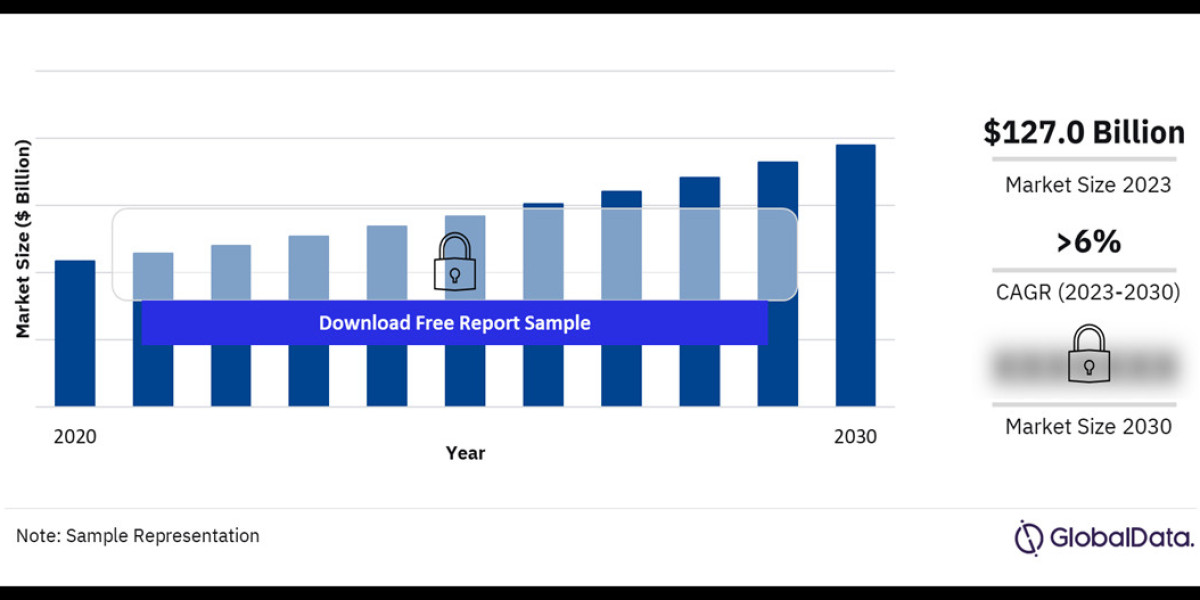

The pharmaceutical packaging market has seen significant advancements in recent years, with innovation focused on enhancing product safety, patient convenience, and environmental sustainability. As new health and safety regulations emerge and the demand for personalized healthcare grows, Pharmaceutical Packaging Market the pharmaceutical industry is embracing cutting-edge packaging solutions to meet these challenges. This article explores the top trends and innovations in pharmaceutical packaging driving the market in 2024, shedding light on how these solutions address key industry needs.

1. Sustainable and Eco-Friendly Packaging

With the global push toward sustainable practices, the pharmaceutical packaging industry is moving away from traditional plastics and embracing eco-friendly materials. Sustainability initiatives are critical in the industry’s efforts to reduce waste and environmental impact, meeting consumer expectations and regulatory requirements.

Key Trends:

- Biodegradable Materials: Companies are investing in biodegradable and compostable materials, such as bioplastics derived from renewable resources, to replace conventional plastic.

- Recyclable and Reusable Packaging: Innovative, recyclable packaging options like glass vials, aluminum cans, and recyclable plastic blister packs are becoming mainstream.

- Minimalist Packaging: To reduce waste, many companies are adopting minimalist packaging designs that use fewer materials without compromising product safety. Get a Snapshot of the Pharmaceutical Packaging Market, Download a Free Report Sample

Leading Examples:

- Amcor: Known for sustainable pharmaceutical packaging solutions, including recyclable and reusable packaging materials.

- Gerresheimer: Develops eco-friendly glass vials and plastic alternatives focused on sustainability and product safety.

2. Smart Packaging and Digital Integration

Smart packaging technologies are transforming the pharmaceutical industry, making it easier to track, monitor, and manage medication. With digital enhancements like QR codes, RFID (radio-frequency identification), and NFC (near-field communication), packaging now offers advanced functionalities to improve patient compliance and streamline supply chains.

Key Features:

- QR Codes and NFC Tags: These allow patients and healthcare providers to access important information, such as dosing instructions and expiration dates, directly from their smartphones.

- Anti-Counterfeiting Technology: Unique digital codes, holograms, and embedded chips help prevent counterfeiting, ensuring that consumers receive authentic products.

- Temperature and Condition Monitoring: Smart packaging can monitor environmental conditions like temperature and humidity, which is especially important for temperature-sensitive drugs like vaccines.

Leading Examples:

- Aptar Pharma: Offers connected packaging solutions that allow patients to scan their medication for personalized support and adherence tracking.

- Stora Enso: Specializes in intelligent packaging with integrated RFID technology, ideal for supply chain monitoring and anti-counterfeiting.

3. Child-Resistant and Senior-Friendly Packaging

Safety and accessibility are essential in pharmaceutical packaging. The industry is innovating with designs that ensure child safety while remaining user-friendly for older adults, a growing demographic that relies on regular medication.

Key Trends:

- Child-Resistant Closures: Packaging with tamper-evident seals, push-and-turn caps, and blister packs that are difficult for children to open help prevent accidental ingestion.

- Senior-Friendly Designs: Easy-to-open packaging with clear labeling, larger text, and ergonomic designs ensure accessibility for seniors, helping them adhere to their medication regimen.

- Dual-Function Packaging: Some packages combine child resistance with easy-open features tailored to specific medications, allowing safe and simple access for intended users.

Leading Examples:

- West Pharmaceutical Services: Known for packaging solutions that combine child resistance and accessibility for seniors, especially in injectables and oral medication formats.

- Berry Global: Provides packaging solutions that incorporate user-friendly features like ergonomic caps and larger print for ease of use.

4. Personalized and Precision Packaging

The shift toward personalized medicine is driving the need for customizable packaging solutions. Packaging tailored to individual doses or specific treatments aligns with trends in precision medicine, enhancing patient compliance and enabling accurate dosing.

Key Features:

- Single-Dose and Multi-Dose Packaging: Packaging designed for exact dosage needs helps reduce the risk of overdose and makes it easier for patients to follow prescribed regimens.

- Patient-Specific Labeling: Personalized labeling with patient information, instructions, and even reminders for usage helps streamline medication management, especially for complex treatment plans.

- Compartmentalized Blister Packs: Dividing doses by day and time in blister packs enhances adherence and minimizes dosing errors.

Leading Examples:

- Catalent: Offers customized packaging services for personalized medicine, providing single-dose and multi-dose packaging options.

- Schott: Known for its vials and syringes specifically designed for personalized medicine, allowing for precise dosing and tailored treatments.

5. Advanced Injectable Packaging for Biologics

With the growth of biologics and biosimilars, which are often sensitive to light, temperature, and other environmental factors, advanced injectable packaging has become essential. Biologics require specialized packaging that maintains stability and sterility, ensuring efficacy throughout the drug’s shelf life.

Key Innovations:

- Pre-Filled Syringes and Cartridges: These make administration easier and safer, especially for patients who self-inject. The sterile, single-use design also minimizes contamination risks.

- Glass and Plastic Vials with Enhanced Stability: Advanced vials that prevent drug interactions with the container material, reducing the risk of drug degradation.

- Dual-Chamber Syringes: For medications that need mixing right before injection, dual-chamber syringes allow for easy combination of active ingredients, maintaining stability and ease of use.

Leading Examples:

- BD (Becton, Dickinson and Company): Offers pre-filled syringe solutions designed to protect biologics from light and temperature variations.

- West Pharmaceutical Services: Specializes in packaging solutions for injectables, including advanced vials and syringes that provide safety and product stability for sensitive drugs.

6. Cold Chain Packaging and Temperature Control Solutions

Temperature-sensitive drugs, like vaccines and biologics, require cold chain packaging solutions to ensure they remain effective during transportation and storage. Cold chain packaging has evolved significantly, with new technologies ensuring that products stay within required temperature ranges, even in extreme climates.

Key Features:

- Phase Change Materials (PCMs): Advanced PCMs can maintain constant temperatures over extended periods, ensuring that sensitive products remain viable throughout transit.

- Temperature-Tracking Sensors: Digital sensors integrated into packaging monitor temperature throughout the supply chain, providing alerts if the temperature exceeds safe levels.

- Insulated Containers and Gel Packs: These keep temperatures stable, protecting sensitive medications from fluctuations during long-haul transport.

Leading Examples:

- Pelican BioThermal: Provides advanced insulated shipping solutions for pharmaceuticals that require strict temperature control.

- Softbox Systems: Specializes in eco-friendly, reusable cold chain packaging with integrated temperature monitoring for biologics and vaccines.

Future Outlook for the Pharmaceutical Packaging Market

The pharmaceutical packaging market is expected to see continued growth and innovation as it addresses evolving industry needs and regulatory pressures. Key areas of future development include:

- Increased Focus on Environmental Impact: As sustainability becomes a global priority, the industry will invest further in biodegradable, recyclable, and reusable materials.

- Expansion of Smart Packaging: With the growing integration of IoT technology, pharmaceutical packaging will evolve to offer even greater functionality, from real-time condition monitoring to advanced anti-counterfeiting measures.

- Enhanced Safety and Accessibility: The demand for child-resistant, senior-friendly, and personalized packaging solutions will continue to grow as consumer demographics shift and more people rely on medication management.

Conclusion

The pharmaceutical packaging market in 2024 reflects the industry's commitment to innovation, safety, and sustainability. With trends like sustainable packaging, smart and personalized solutions, and advanced packaging for biologics, the market is responding to the complex demands of healthcare providers, patients, and regulatory bodies. As these innovations continue to evolve, the future of pharmaceutical packaging looks promising, enabling safer, more effective, and environmentally conscious delivery of critical medications worldwide.