In today's fast-paced manufacturing industry, efficiency and precision are key factors in ensuring the success of a business. One way to boost production capabilities and stay ahead of the competition is by utilizing precision CNC machining services.

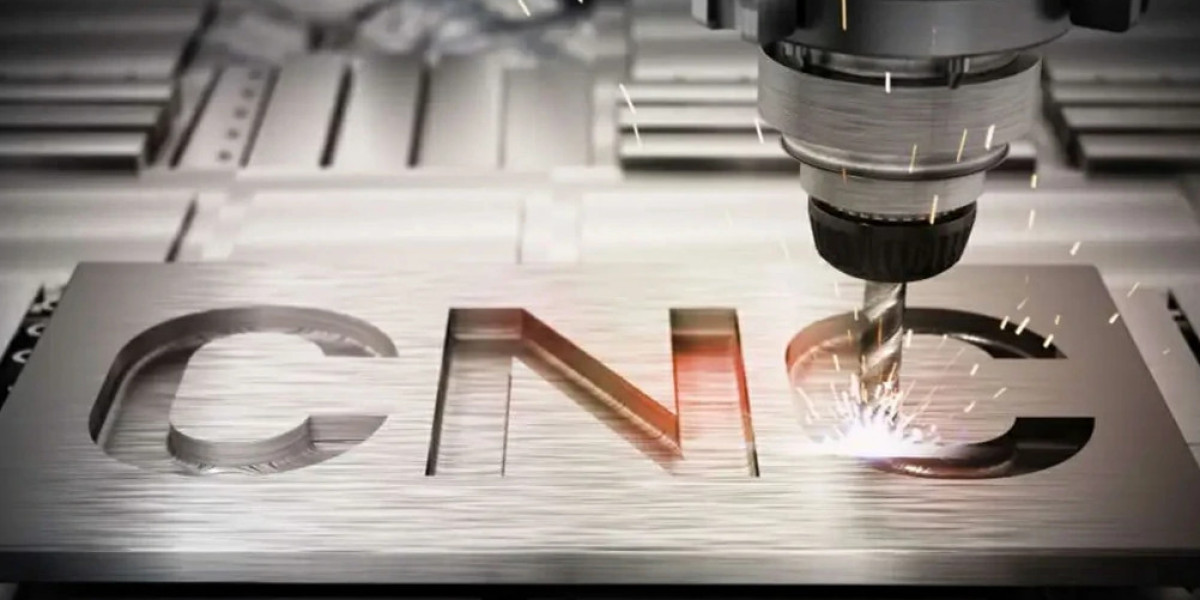

CNC (Computer Numerical Control) machining involves the use of computerized controls to operate and manipulate machining tools such as lathes, mills, and routers. This technology allows for highly precise and repetitive production of complex parts and components with minimal human intervention.

By partnering with a reputable CNC machining service provider, companies can benefit from a wide range of advantages that can help streamline their production processes and improve overall productivity.

One of the primary benefits of using precision CNC machining services is the ability to produce parts with extremely tight tolerances and intricate geometries. CNC machines are capable of performing complex cuts and shapes that would be nearly impossible to achieve with traditional machining methods. This level of precision ensures that parts are manufactured to exact specifications, resulting in higher quality products and reduced waste.

Additionally, CNC machining offers increased production speed and efficiency. Once a CNC program is created and tested, parts can be produced quickly and consistently without the need for manual adjustments or setups. This means that companies can meet tight deadlines and handle high-volume production runs with ease.

Another major advantage of CNC machining is its versatility. CNC machines can work with a wide variety of materials, including metals, plastics, composites, and more. This flexibility allows companies to manufacture a diverse range of components for different industries and applications.

Moreover, CNC machining services can help companies reduce costs and save money in the long run. By eliminating the need for multiple machines and manual labor, CNC machining reduces production times, energy consumption, and material waste. This results in lower production costs and increased profitability for businesses.

Furthermore, CNC machining services can enhance overall product quality and consistency. Because CNC machines operate based on digital programs, they can replicate the same design and specifications accurately every time. This ensures that parts are identical in size, shape, and finish, leading to higher customer satisfaction and brand reputation.

In conclusion, precision CNC machining services offer numerous benefits for companies looking to boost their production capabilities and stay competitive in the market. From increased precision and efficiency to cost savings and improved product quality, CNC machining can revolutionize the way companies manufacture parts and components.

By partnering with a trusted CNC machining service provider, companies can take advantage of cutting-edge technology and expertise to streamline their production processes and achieve optimal results. Whether you are a small business or a large enterprise, investing in CNC machining services can help you achieve your production goals and drive success in today's competitive manufacturing landscape.