A Depth Gauge is a precise measuring tool used to determine the depth of holes, slots, grooves, or cavities from a reference surface. It is widely used in engineering, manufacturing, woodworking, construction, diving, and even quality control labs. Accurate measurements are critical because even small errors can result in faulty products, unsafe structures, or incorrect experimental results.

The concept of depth measurement has been around for centuries. In ancient times, humans used simple sticks or weighted ropes to gauge the depth of wells, rivers, and trenches. While these methods provided approximate measurements, they lacked accuracy. The industrial era brought mechanical tools that allowed precision in engineering and manufacturing processes. Later, dial and digital depth gauges offered even faster, more precise measurements, reducing human error.

Today, depth gauges come in various types, each suitable for specific applications. They are indispensable for professionals and hobbyists who require precise measurements. Understanding their types, working principle, applications, benefits, and maintenance is crucial to using depth gauges effectively.

Evolution and History of Depth Gauges

The history of depth gauges is fascinating, reflecting humanity’s quest for accuracy. Early methods relied on rudimentary tools. Sticks and ropes with weighted ends were used to estimate depth in wells or rivers. While functional, these methods were imprecise and inconsistent.

The industrial revolution marked a turning point. As industries demanded higher precision, mechanical depth gauges were invented. These early gauges consisted of a base that rested on a surface, a sliding probe, and a scale with markings. They allowed measurements that were significantly more accurate than the ancient methods.

The 19th century introduced vernier scales, which further improved precision. With vernier calipers, users could measure depth down to fractions of a millimeter. This innovation became crucial in manufacturing, particularly in the automotive and metalworking industries, where exact dimensions are vital.

In the 20th century, dial depth gauges emerged. They replaced manual reading with a dial indicator, enabling faster and easier measurements. This was particularly useful for repetitive industrial tasks, as it reduced human errors and improved productivity.

With the digital age, digital depth gauge appeared, offering electronic readings on LCD screens. These gauges include advanced features such as automatic zeroing, unit conversion, and data storage. Digital gauges are now widely used in laboratories, precision engineering, and high-tech industries where utmost accuracy is required.

The evolution of depth gauges shows humanity’s increasing need for precision, efficiency, and safety. From sticks to digital instruments, depth gauges have become sophisticated tools essential for multiple industries.

Types of Depth Gauges and Their Applications

Depth gauges are available in several types, each suited to specific tasks. Choosing the correct type ensures precision and efficiency.

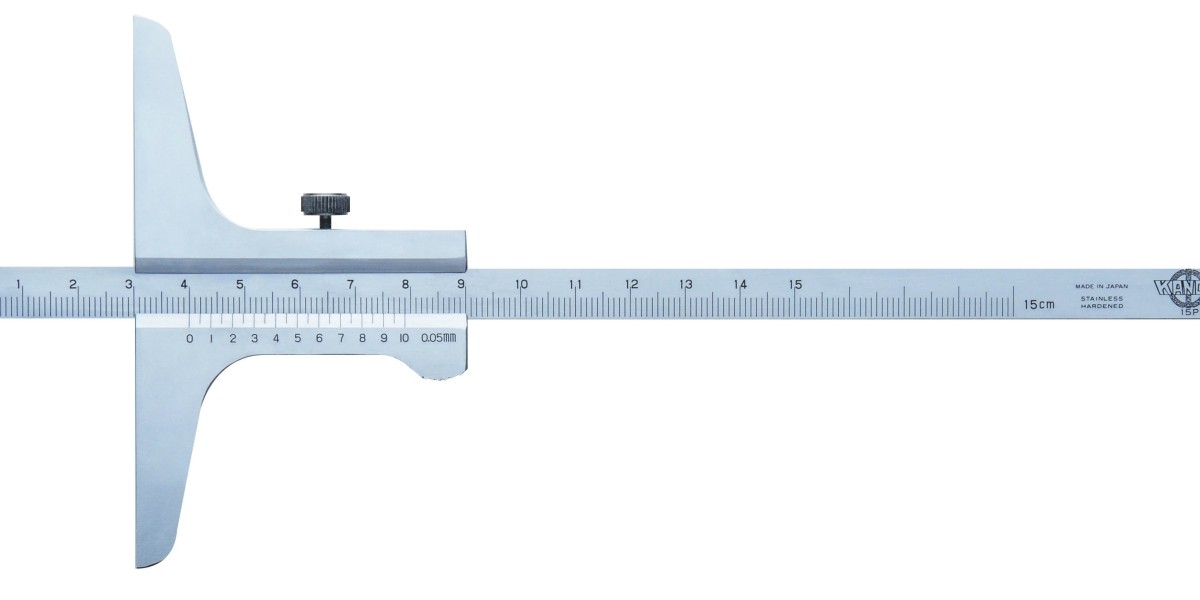

Vernier Depth Gauges are mechanical instruments with sliding scales and vernier markings. They are widely used in laboratories, machining, and woodworking. Vernier gauges require careful reading but provide reliable measurements with high accuracy.

Dial Depth Gauges incorporate a dial indicator for easy and quick readings. They are suitable for industrial environments where repetitive measurements are needed, such as automotive manufacturing and metalworking.

Digital Depth Gauges display readings on an LCD screen. These gauges are user-friendly, precise, and often include features like automatic zeroing, data memory, and unit conversion. Digital gauges are ideal for laboratories, quality control, and engineering tasks requiring high precision.

Micrometer Depth Gauges are specialized for extremely precise measurements. They are capable of measuring minute differences, often up to 0.001 millimeters, and are used in scientific research, precision engineering, and high-tech manufacturing.

Diving Depth Gauges are designed for underwater use. Divers rely on these gauges to monitor depth accurately to prevent decompression sickness and other underwater hazards. Some diving depth gauges include alarms and pressure compensation systems.

Each type serves a specific purpose. Understanding the requirements of your task ensures you select the most appropriate depth gauge, leading to accurate measurements and efficient work.

Working Principle of Depth Gauges

The working principle of a depth gauge is simple: it measures the vertical distance from a reference surface to the bottom of a cavity. However, the design and mechanism vary based on the type of gauge.

Mechanical depth gauges usually consist of a base, probe, and scale. The base rests flat on the reference surface, the probe moves into the hole or groove, and the scale provides the depth reading. Vernier scales allow fine measurement and accuracy down to fractions of a millimeter. Dial gauges replace the scale with a dial, which gives an instant reading for convenience.

Digital depth gauges use electronic sensors to detect probe movement and calculate depth. The measurement is displayed on an LCD screen for easy reading. Features like automatic zeroing and unit conversion make digital gauges user-friendly, especially for repetitive tasks or high-precision measurements.

Accuracy depends not only on the type of gauge but also on correct handling. The base must remain stable and flat, the probe should move smoothly, and excessive force should be avoided. Misalignment or improper handling can result in incorrect readings.

Understanding how a depth gauge works allows users to maximize its accuracy and reliability, whether in industrial applications, woodworking, or laboratory settings.

Benefits of Using Depth Gauges

Depth gauges provide numerous advantages, making them essential tools in many industries:

Accuracy: Ensures precise measurement of holes, grooves, or cavities. This reduces errors and improves product quality.

Consistency: Provides uniform measurements across multiple items, which is vital in production and manufacturing.

Efficiency: Dial and digital gauges allow fast measurements, saving time in repetitive tasks.

Safety: Accurate measurements prevent accidents in construction, engineering, and diving.

Ease of Use: Digital gauges offer automatic features, such as zeroing, unit conversion, and memory, making them user-friendly even for beginners.

Durability: Mechanical and digital depth gauges are built to last with proper care, providing long-term value.

By using a depth gauge, industries and individuals can achieve better quality control, higher efficiency, and safer working conditions.

Applications of Depth Gauges Across Industries

Depth gauges have versatile applications:

Manufacturing and Engineering: Measure holes, slots, and grooves to ensure compliance with design specifications. Automotive engineers use depth gauges to check engine parts, brake components, and machined surfaces.

Woodworking: Depth gauges help check mortises, grooves, and decorative slots, ensuring uniformity and high-quality finishes.

Construction: Used to measure foundation depth, slab thickness, and excavation levels. Accurate measurements ensure structural integrity and regulatory compliance.

Diving: Specialized underwater depth gauges help divers monitor depth and avoid decompression sickness.

Quality Control: Depth gauges are used to verify dimensional accuracy of manufactured products, reducing errors and waste.

Their applications are not limited to professional use; hobbyists, model builders, and DIY enthusiasts also benefit from using depth gauges for precise work.

Maintenance and Care for Depth Gauges

Proper maintenance is essential to ensure a depth gauge’s accuracy and longevity:

Cleaning: Wipe off dust, oil, and debris after each use to prevent rust and damage.

Storage: Keep in protective cases, away from moisture, heat, and direct sunlight.

Calibration: Regular calibration ensures reliable readings. Digital gauges often have self-calibration features.

Handling: Avoid dropping or bending the probe, which can affect accuracy.

Environmental Protection: Protect from corrosive substances, extreme temperatures, and high humidity.

A well-maintained depth gauge provides consistent, precise measurements over time, making it a reliable tool for all applications.

Conclusion

Depth gauges are vital tools for accurate measurements in multiple industries and applications. From simple mechanical vernier gauges to advanced digital models, they provide precision, reliability, and efficiency.

Understanding the types, working principles, benefits, applications, and maintenance of depth gauges allows users to make the most of this essential instrument. Whether in engineering, woodworking, construction, or diving, depth gauges ensure quality, safety, and precision in every measurement.

Questions & Answers

Q1: What is a depth gauge used for?

It measures the depth of holes, grooves, or cavities for accurate results.

Q2: What are the main types of depth gauges?

Vernier, dial, digital, micrometer, and diving depth gauges.