In modern manufacturing, efficiency, hygiene, and product consistency are critical factors for success. Whether in food processing, pharmaceuticals, chemicals, or confectionery production, handling powders can be challenging. Manual processes often lead to contamination, spillage, and material wastage. This is where Powder Transfer Systems come into play, revolutionizing the way industries handle powders and bulk solids.

What Are Powder Transfer Systems?

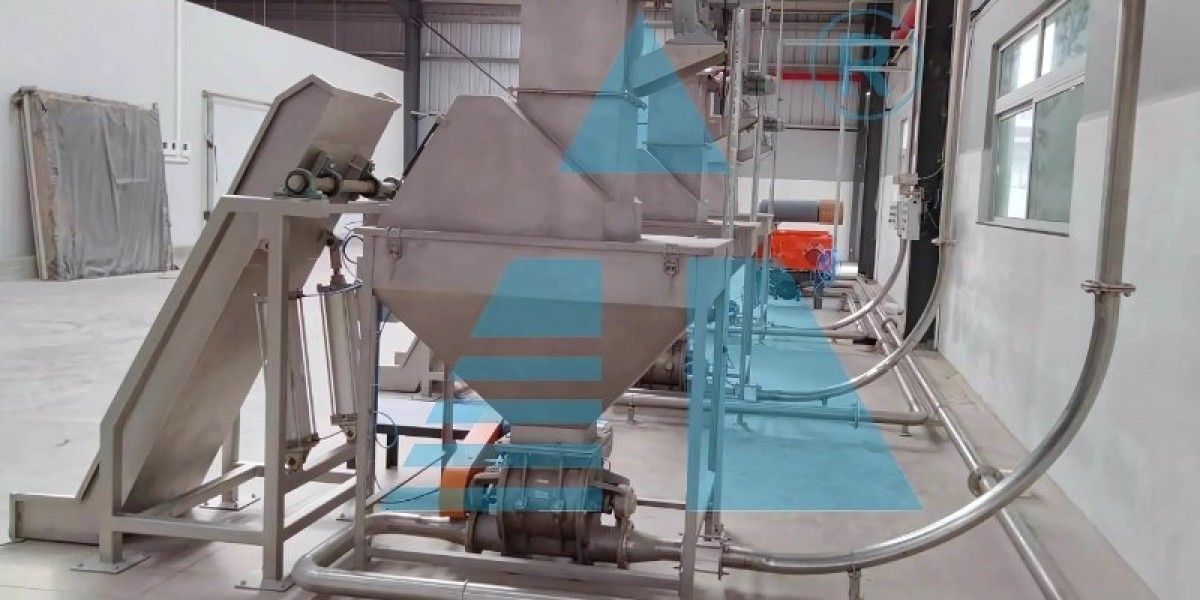

Powder Transfer Systems are specialized equipment designed to transport powders, granules, or bulk solids from one point to another within a manufacturing facility. Unlike traditional methods such as scooping, manual handling, or simple conveyors, these systems use controlled air pressure, vacuum, or mechanical means to move materials efficiently, safely, and hygienically.

Constructed with food-grade stainless steel or industrial-grade alloys, modern Powder Transfer Systems are ideal for environments where hygiene, precision, and consistency are paramount. They can be fully automated, integrated with production lines, and customized for different material types and production capacities.

The Role of Powder Transfer Systems in Improving Efficiency

Efficiency is the backbone of any successful production facility. Powder Transfer Systems enhance efficiency in several key ways:

1. Automated Material Handling

Automation reduces reliance on manual labor, minimizes human error, and ensures smooth material flow throughout the production line. By automating powder transfer, factories can maintain a continuous process, reducing downtime and improving overall productivity.

2. Faster and Precise Transfer

Traditional powder handling methods are often slow and inconsistent, leading to delays in production. Powder Transfer Systems allow rapid, controlled, and precise transfer of materials, ensuring that production lines are supplied on time without interruption. This speed translates into higher throughput and optimized production schedules.

3. Integration with Production Lines

Modern Powder Transfer Systems can be seamlessly integrated into automated production lines. This ensures that powders are delivered exactly when and where they are needed, maintaining the workflow and eliminating bottlenecks in manufacturing processes.

4. Reduction of Labor Costs

Manual handling requires significant labor investment and is prone to inefficiencies. By employing Powder Transfer Systems, manufacturers can reduce labor costs and reallocate human resources to tasks that require more skill, creativity, or oversight.

How Powder Transfer Systems Reduce Waste

Waste reduction is another significant benefit of using Powder Transfer Systems. Handling powders manually or with basic equipment often results in material loss, spillage, or contamination. These systems address these challenges in the following ways:

1. Minimizing Material Loss

Powders are prone to sticking, clumping, or scattering during manual handling. Enclosed Powder Transfer Systems ensure that materials move directly from storage to processing equipment with minimal loss, saving raw materials and reducing production costs.

2. Maintaining Product Quality

Contamination and cross-mixing of powders can compromise product quality. By using Powder Transfer Systems, materials are transported in sealed, hygienic pipelines, preserving purity and consistency. This leads to fewer rejected batches and less wastage.

3. Reducing Spillage and Dust

Powder handling often creates dust clouds and spills, which not only waste material but also pose safety hazards. Enclosed Powder Transfer Systems prevent spillage, contain dust, and maintain a clean production environment, protecting both workers and products.

4. Accurate Portioning and Dosing

Some Powder Transfer Systems come equipped with precise dosing and weighing mechanisms. This ensures that the exact amount of powder reaches each process, eliminating overuse, wastage, or product inconsistencies.

Applications of Powder Transfer Systems

Powder Transfer Systems are versatile and used across multiple industries:

Food Processing: Transporting sugar, flour, cocoa, and other food powders safely and hygienically.

Pharmaceuticals: Handling active ingredients and excipients while maintaining strict quality and safety standards.

Chemicals: Moving fine chemicals or powders in a controlled, dust-free environment.

Confectionery and Chocolate Production: Ensuring smooth, continuous supply of ingredients for chocolate, candies, and other sweets.

Cosmetics: Safe transfer of powders in creams, lotions, and beauty products manufacturing.

These systems prove indispensable in industries where hygiene, precision, and efficiency are critical.

Key Features to Look for in a Powder Transfer System

When investing in a Powder Transfer System, consider the following features to maximize efficiency and minimize waste:

Enclosed Design: Prevents contamination, dust, and spillage.

Stainless Steel Construction: Ensures hygiene and corrosion resistance.

Automated Controls: Allows integration with production lines for consistent and precise operation.

Flexible Capacity Options: Suitable for small, medium, or large-scale production.

Ease of Cleaning: CIP (Clean-In-Place) compatibility for maintaining hygiene standards.

Conclusion

In today’s competitive manufacturing environment, efficiency, quality, and sustainability are essential. Powder Transfer Systems offer a reliable solution for handling powders and bulk materials efficiently, safely, and hygienically. By automating material transfer, reducing labor costs, and minimizing waste, these systems help manufacturers optimize production, maintain product quality, and save on raw materials.