Any vehicle remains inefficient without a quality engine. The prime purpose of an engine is to convert fuel into energy. This way, it keeps equipment running smoothly. Parts inside an engine may wear out due to long operational hours or friction over time. Performance, as a result, drops when such things happen.

Besides, fuel use also rises apart from sudden breakdowns. In such instances, using the right spare part will keep the engine running smoothly for a longer time frame. Welcome to this all-encompassing guide that explains the key components of the engine & their purpose. You can also understand how quality engine spare parts can protect your vehicle smoothly.

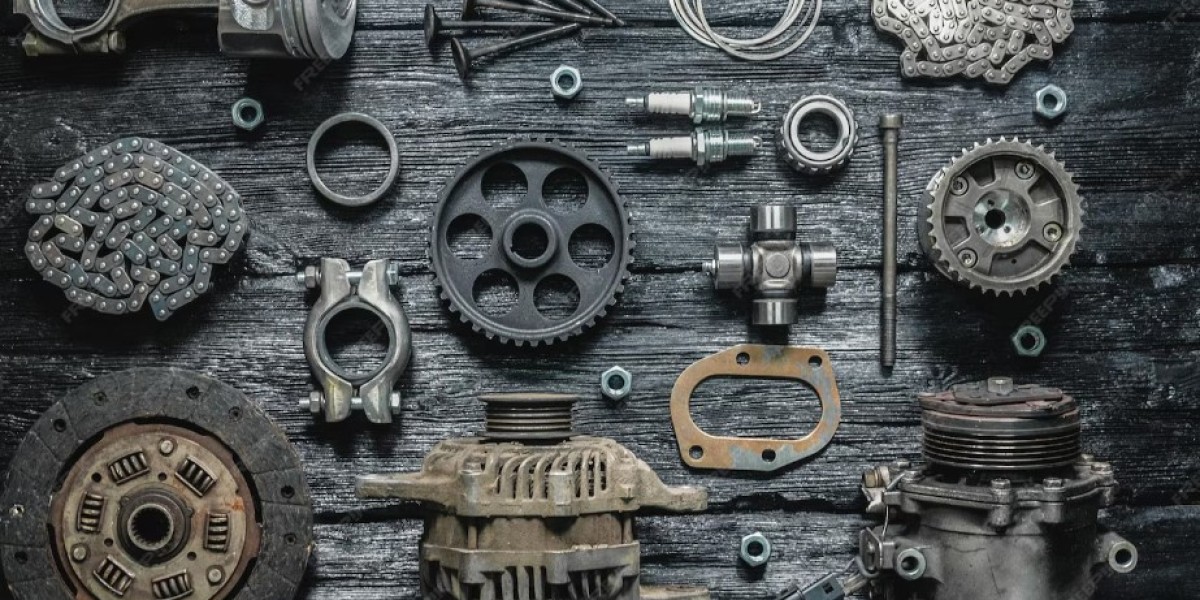

Meaning of Engine Spare Parts

Engine spare parts are replacement elements used when original parts wear out. What these parts do is restore proper functioning while keeping the engine smooth during heavy operations. Using quality spares supports better fuel economy as well as smoother performance.

Those parts that are built with poor quality may reduce performance. It may impact several other elements once a part fails. This results in costly repairs or extended downtime. Here are the top benefits of quality engine spares –

An excellent fit with existing systems

Improved combustion efficiency

Lower wear on moving components

Compliance with safety as well as emission norms

Longer service intervals

Reduced fuel waste

Major Engine Spare Parts and Their Functions

Each part plays a unique role in how the engine performs. Knowing how these parts work helps detect issues early.

Cylinder Block

The cylinder block forms the foundation of the engine. It holds cylinders that guide the pistons during motion. This block must handle high pressure and temperature. Cracks or leaks in the block can reduce compression and lead to overheating.

Crankshaft

The crankshaft converts the straight movement of the piston into circular motion. That motion transfers to the transmission system. A balanced crankshaft limits vibration while keeping power delivery smooth. A crankshaft that is damaged may result in loss of power.

Connecting Rod

The connecting rod joins the piston with the crankshaft. It transfers the force created during combustion to the crankshaft. The rod must stay straight & strong to handle stress during high-speed movement. Note that a poorly connecting rod may result in reduced efficiency.

Camshaft

The camshaft controls the opening as well as closing of intake and exhaust valves. Proper timing ensures clean combustion and correct air-fuel mixture. Damaged cam lobes may disturb valve timing. This results in low power or sometimes rough idling.

Pistons with Rings

Pistons compress the air as well as fuel inside a cylinder. Piston rings seal the space between the piston as well as cylinder wall. This seal prevents gas leaks while managing oil film on the surface. Weak compression rings reduce power output. It may result in oil burning or smoke from the exhaust.

Cylinder Liner

The cylinder liner offers a surface that’s resistant to wear. It reduces friction as well as prevents scratches on the block. Liners protect the block from heat & pressure damage. Replacing the liners at the right time will extend the engine’s life.

Turbocharger

A turbocharger forces more air into your engine. This results in better combustion. It also improves output without increasing engine size. A faulty turbo may cause a whistling noise or poor acceleration. Using a durable turbocharger supports cleaner burning and better fuel economy.

Water Pump

The water pump circulates coolant through the engine system. It removes excess heat and keeps temperature steady. A failed pump causes overheating, which can damage pistons, gaskets, or cylinder heads. Regular inspection of coolant flow prevents serious engine issues.

Oil Filter

The oil filter keeps dirt & carbon away from engine oil. Clean oil will lower the friction between those moving parts. A clogged filter restricts oil flow. This increases wear. Replacing filters on time ensures smooth lubrication.

Fuel Filter

The fuel filter will trap the impurities before the fuel reaches the injectors. Note that dirty fuel may result in misfiring or even injector damage. On the other hand, regular replacement keeps fuel clean while combustion remains efficient.

Flywheel with Housing

The flywheel stores energy from each power stroke to maintain smooth rotation. It supports gear shifting because it perfectly balances their motion. The housing covers & supports the flywheel structure. Damage to these parts may cause vibrations or poor clutch function.

Crankshaft Pulley

The crankshaft pulley transfers engine rotation to auxiliary systems like the alternator or water pump. It keeps the systems running smoothly based on the engine speed. The pulley will bring belt noise as well as poor accessory function when it is misaligned.

The Role of Quality Spare Parts

Using genuine engine spare parts helps machines perform better under tough working conditions. Quality components improve durability. At the same time, they reduce repair frequency. Inferior substitutes often wear faster or result in an imbalance between connected systems. Quality parts reduce friction while limiting heat buildup as well as supporting proper lubrication.

Genuine spares save time as well as energy. At the same time, it reduces the repair expenses. It also maintains engine warranty as well as safety standards. The right parts ensure uninterrupted operation for equipment that runs daily.

What Can Customers Face Related to Engine Spares?

Many users face common problems with low-grade or fake spare parts:

Shutting down of the engine during work unexpectedly

Maintenance costs rising

Oil leaks frequently

Longer downtime

More repairs

Poor mileage

Premature wear

Such issues impact productivity as well as profit. Picking the quality spares from verified suppliers prevents such losses. Speedy access to genuine parts also reduces waiting time for maintenance teams.

How to Identify Good Quality Spare Parts

The machine downtime can create financial loss for industries that depend on equipment. Reliable parts improve fuel efficiency. Note that genuine spares maintain correct clearances between moving parts. As a result, they support functions even under stress.

Companies using quality components report fewer service calls & reduced fuel waste. Long service life may reduce the operating expense. Here are the signs indicating the premium quality of spare parts:

The right dimensions as well as fitment marks

Secure packaging with quality labelling

Excellent material that comes with a great finish

You always need to avoid parts that appear roughly cast or have mismatched finishes or colours. Testing compatibility before installation saves future trouble.

When Is Replacement Needed?

A few notable signs that your engine part needs replacement are mentioned below -

Blue or black smoke from the exhaust

Drop in power or acceleration

Oil contamination or low oil pressure

Increased vibration under load

Unusual noise during start or idle

Overheating despite coolant circulation

Timely action reduces damage to nearby parts and lowers repair cost.

Wrapping up

A reliable engine keeps operations steady across on-road, off-road, or marine applications. Consistent use of quality spare parts ensures correct balance between performance, safety, and fuel use. Proper maintenance with genuine engine spare parts will reduce frequent breakdowns. Getting tested spare parts is about keeping your equipment reliable every single day.

FAQs

How can I confirm a part’s authenticity?

Check packaging, labelling, and supplier authorisation.

Do you need to replace filters or oil components more often?

You should follow service schedules based on running hours or distance.

What causes engine parts to fail early?

Here are the things that result in failure-

Poor maintenance

Low-quality materials

Contamination or

Overheating

How does preventive maintenance help?

It avoids sudden failures while reducing downtime & extending the engine’s service life.