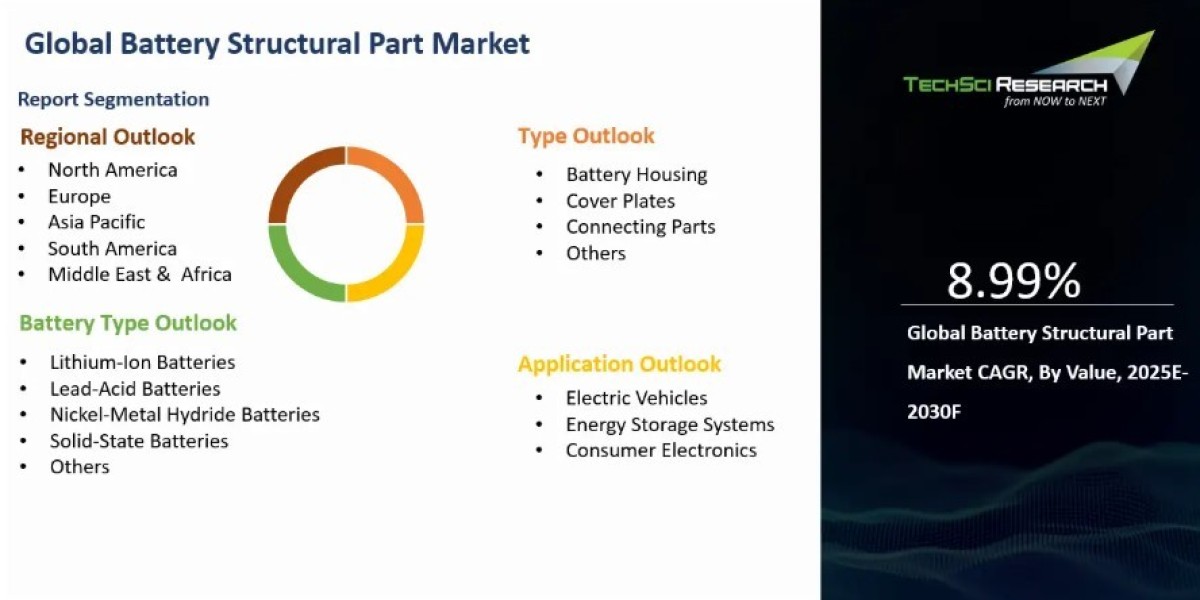

According to TechSci Research report, “Battery Structural Part Market – Global Industry Size, Share, Trends, Competition Forecast & Opportunities, 2030F”, the Battery Structural Part Market was valued at USD 12.97 Billion in 2024 and is expected to reach USD 21.94 Billion by 2030 with a CAGR of 8.99%. The battery structural part market is being propelled by a convergence of factors that underscore its critical role in the broader energy storage and electric mobility ecosystem. One of the primary drivers is the accelerating adoption of electric vehicles (EVs) worldwide, which has created unprecedented demand for advanced and durable battery structural components such as housings, trays, frames, and enclosures that ensure safety, reliability, and thermal management of battery packs.

As automotive manufacturers push toward lighter, stronger, and more compact battery systems to extend driving range and enhance performance, the need for structural parts made from high-strength, lightweight materials like aluminum alloys, composites, and advanced steels has surged. Simultaneously, the rapid growth of renewable energy storage systems, particularly large-scale grid storage and decentralized energy solutions, is driving demand for structural battery components that can withstand heavy cycling, long service life, and diverse environmental conditions.

Safety regulations and stringent quality standards across industries are also fueling innovation in design and material selection, pushing companies to deliver structural parts that not only meet performance benchmarks but also enhance fire resistance, crash safety, and thermal stability. The expansion of global manufacturing capabilities, supported by government initiatives to promote clean energy and electric mobility, has further intensified demand for structural battery parts, particularly in regions like Asia Pacific and Europe, where EV adoption and energy storage deployment are accelerating rapidly.

Technological advancements in precision manufacturing, including CNC machining, die casting, and additive manufacturing, are enabling higher customization and cost efficiency, supporting large-scale production of structural components tailored to specific battery chemistries and configurations. Furthermore, the integration of smart features such as sensors and cooling channels into battery housings is emerging as a differentiator, enhancing overall battery management systems and boosting market growth.

The surge in consumer electronics and portable energy storage solutions also contributes to the market’s expansion, as compact yet robust battery enclosures are essential to product durability and safety. Supply chain optimization and strategic collaborations between automakers, battery manufacturers, and component suppliers are shaping the competitive landscape, enabling innovation and cost reduction while ensuring steady raw material availability.

Environmental concerns and sustainability targets are also steering the market toward recyclable and eco-friendly materials, offering both compliance advantages and market differentiation for manufacturers. Collectively, these dynamics are not only reinforcing the importance of battery structural parts but also creating an environment where continuous innovation, regulatory alignment, and strategic investments will play a decisive role in shaping long-term growth, positioning the market as an indispensable pillar of the global transition toward clean energy and electrified transportation.

Download Free Sample Report

https://www.techsciresearch.com/sample-report.aspx?cid=30627

Customers can also request 10% free customization in this report.

Based on the Battery Type, Lithium-Ion Batteries segment held the largest Market share in 2024. The lithium-ion battery segment is a primary driver of growth in the battery structural parts market, fueled by the rising adoption of electric vehicles, renewable energy storage systems, and portable electronic devices that rely heavily on high-performance energy solutions. Structural parts, including battery housings, trays, enclosures, and thermal management components, play a critical role in ensuring the safety, stability, and durability of lithium-ion batteries, making them indispensable as demand accelerates.

The global transition toward electrification in the automotive sector, supported by government incentives and strict emission reduction targets, has led to massive investment in electric vehicle production, which in turn is amplifying the requirement for advanced, lightweight, and crash-resistant battery structural parts. Manufacturers are increasingly focusing on using high-strength materials such as aluminum, composites, and advanced polymers to optimize energy density while reducing overall vehicle weight, thereby improving efficiency and extending driving ranges.

The proliferation of renewable energy projects has also amplified the need for stationary lithium-ion battery storage solutions, creating additional demand for robust structural components capable of withstanding long operational lifecycles in diverse environmental conditions. Furthermore, consumer electronics and industrial applications, including robotics, power tools, and backup systems, are fueling consistent demand for compact and efficient lithium-ion batteries, further strengthening the market for structural parts that ensure safety and thermal stability in confined designs.

As technology advances, the integration of smart battery systems and modular designs is pushing structural part suppliers to innovate in terms of design flexibility, recyclability, and cost-effectiveness, aligning with sustainability goals. Additionally, supply chain expansions in Asia Pacific, Europe, and North America are creating favorable conditions for local and global suppliers of battery structural parts to scale production and cater to the surging lithium-ion battery demand across multiple industries.

The growing emphasis on safety standards and regulations in energy storage and electric mobility underscores the importance of precision-engineered structural parts to prevent thermal runaway, fire hazards, and mechanical failures. This convergence of electrification trends, regulatory frameworks, and technological innovation firmly positions the lithium-ion battery segment as a key driver of the battery structural parts market, offering substantial opportunities for manufacturers to capture long-term growth while contributing to the global shift toward sustainable energy solutions.

Based on region, Asia Pacific is the fastest-growing region in the battery structural part market, driven by rapid expansion of electric vehicle manufacturing, large-scale battery production, and government-backed clean energy initiatives. The region benefits from the presence of leading battery producers and automakers, coupled with significant investments in gigafactories and advanced manufacturing facilities. Growing demand for lightweight and thermally efficient structural components is fueling innovation in material technologies such as aluminum, composites, and high-performance polymers. Additionally, rising urbanization, supportive policy frameworks, and the shift toward sustainable mobility solutions are creating strong demand, positioning Asia Pacific as a key hub for long-term market growth.

Major companies operating in the Global Battery Structural Part Market are:

Contemporary Amperex Technology Co. Limited (CATL)

Panasonic Corporation

LG Chem Ltd.

Samsung SDI Co., Ltd.

BYD Company Limited

Tesla, Inc.

A123 Systems LLC

Johnson Controls International plc

Saft Groupe S.A.

GS Yuasa Corporation

Download Free Sample Report

https://www.techsciresearch.com/sample-report.aspx?cid=30627

Customers can also request 10% free customization in this report.

“The Global Battery Structural Part Market is expected to rise in the upcoming years and register a significant CAGR during the forecast period. The battery structural part market is positioned for substantial growth, driven by the accelerating adoption of electric vehicles and renewable energy storage systems. Rising demand for lightweight, durable, and thermally efficient components such as housings, trays, and frames is fostering the development of advanced materials, including aluminum alloys, composites, and high-strength polymers. Automakers’ emphasis on weight reduction to extend vehicle range underscores the strategic importance of optimized structural solutions.

Simultaneously, large-scale investments in gigafactories and battery manufacturing facilities are creating robust supply chain opportunities. Furthermore, the shift toward modular and recyclable designs supports sustainability goals, enhancing long-term market competitiveness. Therefore, the Market of Battery Structural Part is expected to boost in the upcoming years.,” said Mr. Karan Chechi, Research Director of TechSci Research, a research-based global management consulting firm.

“Battery Structural Part Market - Global Industry Size, Share, Trends, Opportunity, and Forecast, Segmented, By Type (Battery Housing, Cover Plates, Connecting Parts, and Others), By Application (Electric Vehicles, Energy Storage Systems, and Consumer Electronics), By Battery Type (Lithium-Ion Batteries, Lead-Acid Batteries, Nickel-Metal Hydride Batteries, Solid-State Batteries, Others), By Region, By Competition, 2020-2030F”, has evaluated the future growth potential of Global Battery Structural Part Market and provides statistics & information on the Market size, structure, and future Market growth. The report intends to provide cutting-edge Market intelligence and help decision-makers make sound investment decisions., The report also identifies and analyzes the emerging trends along with essential drivers, challenges, and opportunities in the Global Battery Structural Part Market.

Contact

Techsci Research LLC

420 Lexington Avenue,

Suite 300, New York,

United States- 10170

Tel: +13322586602

Email: sales@techsciresearch.com

Website: www.techsciresearch.com