Introduction

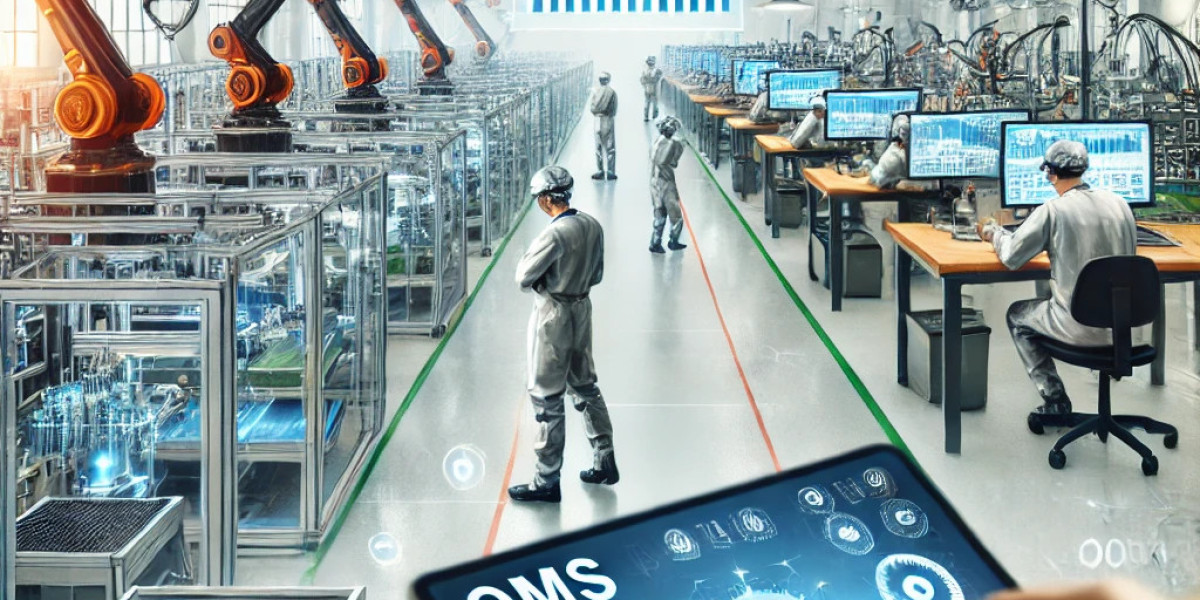

Risk management is a critical aspect of electronics manufacturing. From supply chain disruptions to quality failures, risks can have significant financial and reputational repercussions. A robust QMS for electronics manufacturing provides the framework to identify, assess, and mitigate these risks effectively.

The Importance of Risk Management in Electronics Manufacturing

Complex Supply Chains: Dependence on global suppliers increases vulnerability.

Rapid Innovation Cycles: Accelerated product development can lead to oversight.

Regulatory Pressure: Non-compliance can result in heavy fines and recalls.

How QMS Supports Risk Management

Proactive Identification of Risks:

QMS integrates tools like Failure Mode and Effects Analysis (FMEA).

Helps anticipate potential failures during production.

Document Management System:

Ensures proper documentation of risk assessments and mitigation plans with the help of a document management system.

Enhances traceability and accountability.

Enhanced Quality Control:

Real-time monitoring reduces defect rates.

Preventive measures minimize customer complaints.

Complaint Management Systems:

Streamlines the tracking of customer feedback and issues, enhancing complaint management processes for improved customer satisfaction.

Provides insights into recurring risks.

Best Practices for Implementing Risk Management with QMS

Adopt a Risk-Based Approach: Focus resources on high-impact risks.

Leverage Technology: Use analytics and AI for predictive risk assessment.

Engage Stakeholders: Include cross-functional teams in risk management processes.

Case Studies: QMS in Action

Example: A semiconductor manufacturer used ComplianceQuest’s QMS to implement a risk-based approach, reducing downtime by 30% and improving customer satisfaction.

Why ComplianceQuest QMS is Essential for 2025

In a landscape where risks evolve rapidly, ComplianceQuest provides the tools necessary for effective management:

Integration with document management systems.

Advanced analytics for quality control.

Comprehensive complaint management features.

Conclusion

Managing risks in electronics manufacturing is no small feat, but a robust QMS makes it manageable. ComplianceQuest equips manufacturers with the capabilities to foresee challenges, take corrective actions, and ensure consistent product quality, making it an indispensable partner for 2025 and beyond.