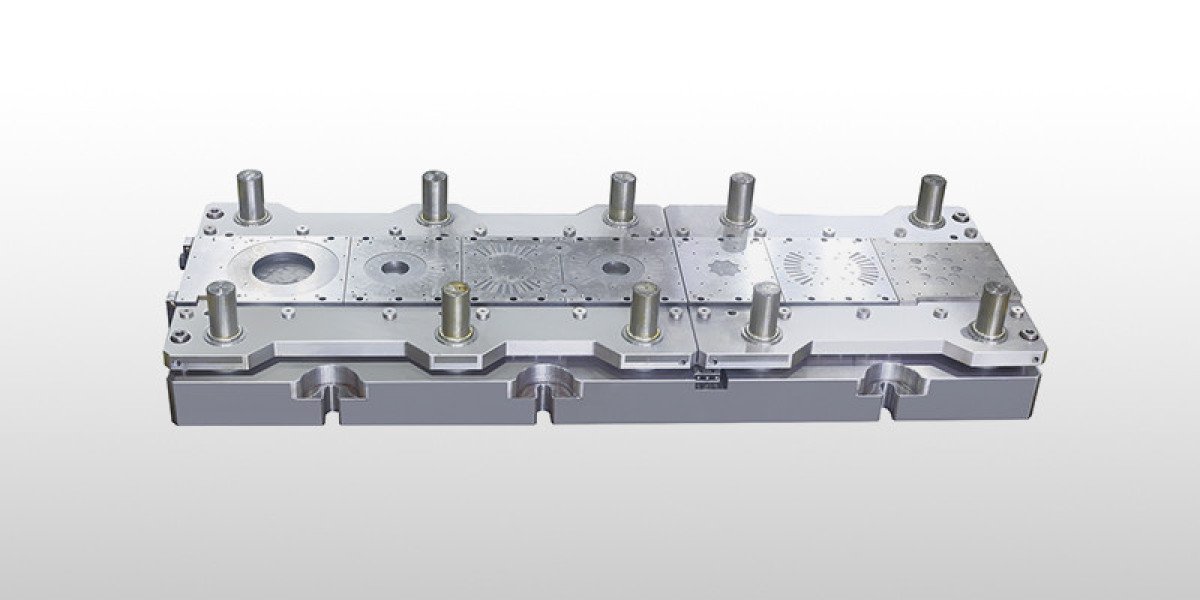

The design of cooling systems in motor molds is a crucial aspect that directly affects production efficiency. While effective, traditional cooling methods may not provide the uniform cooling required for complex mold geometries. In contrast, conformal cooling offers significant advantages in terms of heat dissipation and part quality, although it comes with increased complexity and cost. The choice of coolant media also plays a vital role in optimizing cooling performance. As manufacturers continue to seek ways to enhance efficiency and quality, the importance of effective cooling system design in motor molds will only grow, shaping the future of motor component production.