Introduction

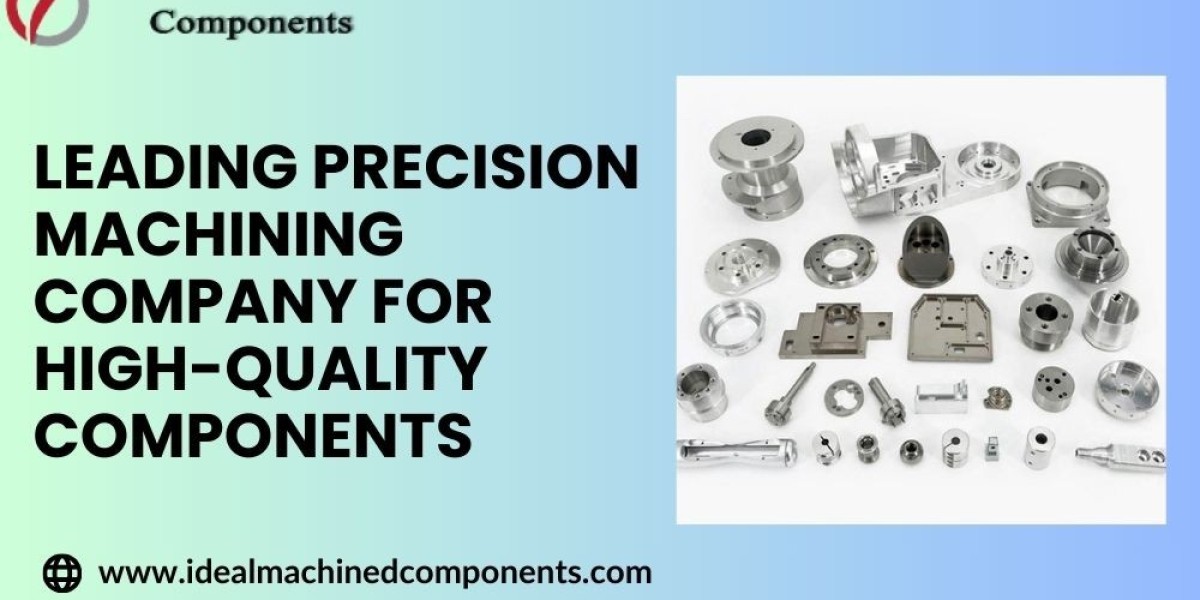

Ideal Machined Components offers precision machining services to its clientele, providing an ideal end-user manufacturing solution. This trusted CNC turning company supplies its products to medical, industrial, and aerospace industries applications; hence, it makes very accurate and consistent customer parts. This precision machining company is a top-notch manufacturer that many medical machining companies consult when critical tolerances and strict regulations must be satisfied. This blog explores a glimpse of how the company stands as a CNC turned parts manufacturer and turned parts supplier, ensuring accuracy and reliability in its operations.

What Defines a Top Precision Machining Company

At its very best, precision machining companies will work on specific standards with strong process control and transparent quality systems. The operation at Ideal Machined Components employs high-end equipment and skills and is driven by an eye for detail. Precision machining marks tighter tolerances, better surface finishes, and reproducible performance.

Ideal Machined Components is a CNC turning company that can handle complex, cylindrical parts, shafts, and geometries beyond the capacity of many generic manufacturers. They can act as a turned parts supplier, aligning their operation with schedules of delivery, certifications of materials, and inspection reports. This is what differentiates Ideal Machined Components among medical machining companies and turned parts suppliers.

Serving the Medical Sector Among Other Industries

The machining of a medical component often comes with a stringent requirement for compliance and traceability. Ideal Machined Components fulfills a role among medical machining companies; it can provide parts manufactured from medical-grade alloys with tight tolerance CNC turning. The company functions as a CNC turned parts manufacturer for things such as implants, surgical instrument parts, or system components, all subjected to surface finishes and biocompatibility considerations.

Other industries also use these capabilities, but the additional conditions associated with medical use make the precision machining company’s work reach a higher level. They also provide consistency between batch deliveries, documentation, and process validation as a supplier of turned parts.

Capabilities of the CNC Turning Company

A CNC turning company involved in using lathes as well as multi-axis turning centers with live tooling to fabricate complicated parts made of either bar stock, forgings, or castings. By the term CNC turning company, one means that there is rapid setup, high consistency, and efficient production of cylindrical or rotational geometries. Companies like Ideal Machined Components are quality precision machining companies that utilize turning in tight tolerances, good concentricity, while providing smooth finishes. This translates to a CNC turned parts manufacturer needing fewer post-operational setups, handling less rework, and achieving shorter lead times. This is exactly the kind of performance that large engineers sourcing from a good turned parts supplier expect.

Key Capabilities Table

Capability | Description | Industry Application |

|---|---|---|

Precision Machining | High-accuracy CNC milling and turning | Aerospace, Automotive, Energy |

CNC Turning | Multi-axis turning for cylindrical components | Industrial Equipment, Valves |

Medical Machining | Tight-tolerance parts with biocompatible materials | Surgical Instruments, Implants |

Prototype to Production | Low-volume and high-volume runs | All manufacturing sectors |

Quality Inspection | Dimensional and visual quality checks | Every production batch |

The above table summarizes the key values of Ideal Machined Components as a precision machining establishment, that of a CNC turning company, as well as an excellent and reliable CNC turned parts manufacturer that also sells its wares as a turned parts supplier into many industries that include even those served by medical machining companies.

Why Choose a CNC Turned Parts Manufacturer?

A large-scale project that needs close tolerance and reliable delivery would require a very good CNC turned parts manufacturer. Ideal Machined Components, having a proficiency in precision machining, combines turning, milling, drilling, and finishing all in one site. It acts as a turned parts supplier because it provides prototype and production volumes. It is what matters when clients, like those belonging to the medical, aerospace, energy, or industrial equipment sectors, compare medical machining companies with CNC turning companies- how they scale from one unit to thousands. The reputation of the company is such that it shows how a precision machining company becomes a partner and not just a vendor.

Turned Components Supplier Role in the Supply Chain

Being a turned part supplier in today's manufacturing supply chain implies more than just physical production; it means aligning with design engineers, providing feedback, control plans, and consistency of quality output. Ideal Machined Components operates in this manner by having robust documents, alignment with customer specifications, and repeat delivery of parts. In precision machining, they integrate inspection, process control, and production planning. Indeed, clients in search of medical machining companies or CNC turning companies value the comprehensive services the turned parts supplier has to offer as part of such an operation.

Quality, Certifications, and Assurance Practices

In fact, a leading precision machining company would have stringent quality systems and certifications. During inspection, documentation of the process, dimensional control, and finishing of Ideal Machined Components is of concern. Compliance is critical for any such medical machining company that deals with regulated product components.

Working in the area of CNC turning and CNC turned parts manufacturing means that all processes are monitored and controlled by the entity. As a turned parts supplier, they deliver more than machined items; they deliver full traceability with batch reports. This gives clients confidence that the precision machining company has what it takes to meet critical tolerances and regulatory requirements within demanding timelines.

Continuously Evolving Technologies in Precision Machining

New technologies, such as automation, live tooling, high-speed spindles, and digital inspection, used in modern manufacturing, dictate that a precision machining company has to be updated. Being a CNC turning company and CNC turned parts manufacturer, Ideal Machined Components invests in and upgrades its equipment. The advantages are even more pronounced in medical machining companies because they apply advanced turning and milling with tight tolerances and efficient setups. The trend, therefore, is emphasized as to why clients seek a turn parts supplier with updated machinery and process capability instead of general machining companies.

Conclusion

The right precision machining company goes a long way in this age of accuracy, traceability, and speed that defines competitiveness. Ideal Machined Components stands out among the few really reliable CNC turning companies, capable CNC turned parts manufacturers, and very responsive turned parts suppliers. While there are numerous medical machining companies operating in the marketplace, this company ranks as one of the finest because of its broad capabilities across industries and consistent performance. Aligning with a proven precision machining company is the first step in the right direction in the case of a quality component that must be made under stringent specifications.

CTA

For a discussion on your next project on precision machining, contact Ideal Machined Components. Be it a CNC turning company that specializes among the medical machining companies, a competent CNC turned parts manufacturer, or a turned parts supplier, Ideal Machined Components will help deliver high-quality components on time.

Call- +(647) 294-5240 Email- info@idealmachinedcomponents.com