The photomask inspection market is expected to witness steady growth as semiconductor manufacturers continue investing in advanced fabrication technologies. Increasing complexity in chip designs, rising demand for precision, and the expansion of semiconductor production facilities are creating strong opportunities for inspection system providers. At the same time, the industry faces technical and operational challenges that will shape future development.

Market Drivers Supporting Industry Forecast

Several strong drivers are influencing the growth outlook of the photomask inspection industry. Shrinking process nodes require higher inspection accuracy to detect defects that can impact yield. Rising demand for advanced chips across electronics, automotive, and communication sectors further strengthens the need for reliable inspection systems. These factors collectively support long-term industry expansion.

Investment Opportunities in Advanced Inspection Technologies

Investment opportunities are increasing as manufacturers seek next-generation inspection solutions. Capital spending is focused on systems that offer higher resolution, faster throughput, and better automation. Investments in advanced imaging, data analytics, and intelligent software platforms are expected to drive innovation and create new growth avenues for inspection equipment suppliers.

Expansion of Semiconductor Fabrication Facilities

The global expansion of semiconductor fabrication facilities is a major contributor to market growth. New fabs require comprehensive inspection infrastructure to maintain quality standards from the start of production. Upgrades to existing facilities also create demand for modern inspection tools that support advanced manufacturing processes and higher production volumes.

Automation Driving Future Industry Development

Automation continues to play a central role in the industry forecast. Automated inspection systems reduce manual workload, improve consistency, and support high-volume manufacturing. Future investments are expected to focus on fully automated solutions that integrate inspection seamlessly into production workflows, improving speed and reliability.

Role of Advanced Lithography in Market Growth

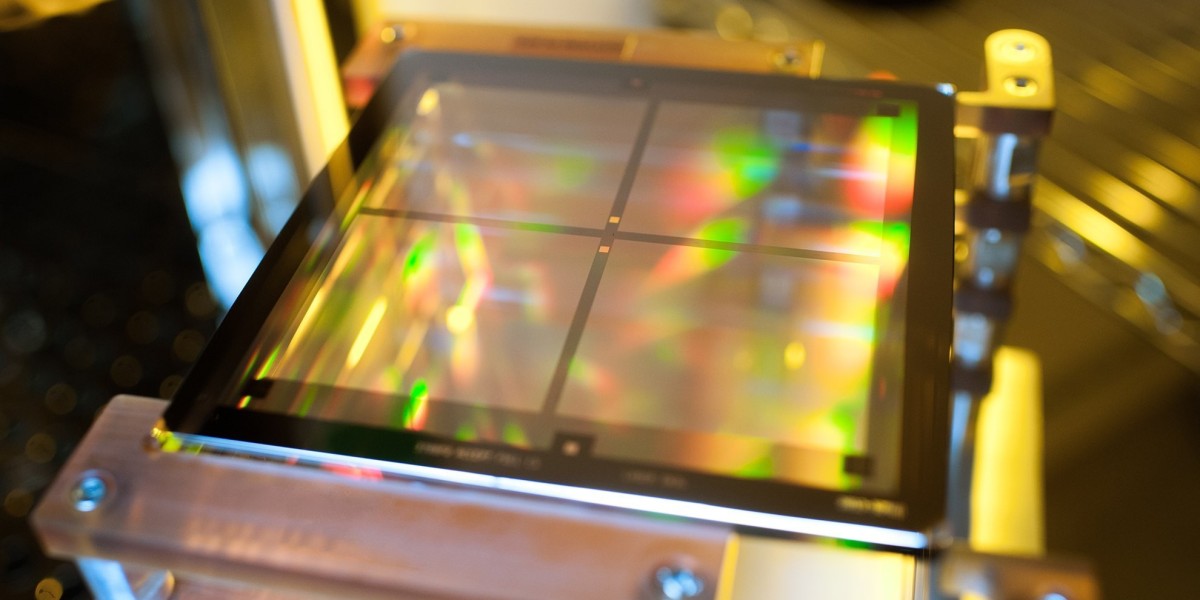

Advanced lithography techniques increase inspection complexity and raise quality expectations. Photomasks used in advanced lithography must meet extremely tight tolerances. Inspection systems capable of detecting minute variations will see increased demand, supporting market growth and technological advancement.

Emerging Challenges in Inspection Accuracy

As inspection requirements become more demanding, achieving consistent accuracy presents challenges. Detecting extremely small defects without increasing false positives requires continuous improvement in imaging and software. Balancing speed and sensitivity remains a key technical challenge that vendors must address.

Cost Pressures and Capital Investment Challenges

High equipment costs can limit adoption, particularly for smaller manufacturers. Advanced inspection systems require significant capital investment, which may delay purchasing decisions. Vendors are responding by offering scalable and modular solutions that provide flexibility and long-term value.

Data Management and Integration Challenges

Inspection systems generate large volumes of data that must be managed efficiently. Integrating inspection data with existing fab systems can be complex. Ensuring compatibility, data accuracy, and real-time accessibility remains a challenge for manufacturers adopting new inspection platforms.

Importance of Yield Protection and Cost Control

Yield protection is a critical driver of inspection investment. Early defect detection prevents costly wafer losses and improves overall profitability. Inspection systems that support yield improvement help justify investment by reducing long-term manufacturing costs and operational risks.

Regional Investment Trends

Asia-Pacific continues to lead investment in photomask inspection due to strong semiconductor manufacturing activity. North America focuses on advanced technology development and innovation, while Europe emphasizes precision manufacturing and quality compliance. Regional priorities influence technology adoption and investment strategies.

Competitive Landscape and Strategic Focus

Competition within the industry is driving continuous innovation. Vendors focus on enhancing system performance, automation, and software intelligence. Strategic partnerships with semiconductor manufacturers support tailored solutions that meet evolving production needs and strengthen competitive positioning.

Sustainability and Operational Efficiency Goals

Sustainability is becoming increasingly important in semiconductor manufacturing. Efficient inspection systems reduce waste, energy consumption, and rework. Investments in automation and optimization support environmentally responsible production while improving operational efficiency.

Long-Term Industry Outlook

The photomask inspection industry forecast remains positive, supported by ongoing semiconductor expansion and technological advancement. Despite challenges related to cost, integration, and accuracy, demand for high-performance inspection systems will continue to grow. Innovation and strategic investment will shape the future of the industry.

Conclusion

Photomask inspection industry forecasts highlight strong investment opportunities driven by semiconductor growth and advancing technologies. While challenges remain, continued innovation and automation will support market expansion. Inspection systems will remain essential for ensuring quality, yield, and reliability in global semiconductor manufacturing.